Vertical Mill Hollow Balls

Vertical Mill Grinding Balls HTHI Castings

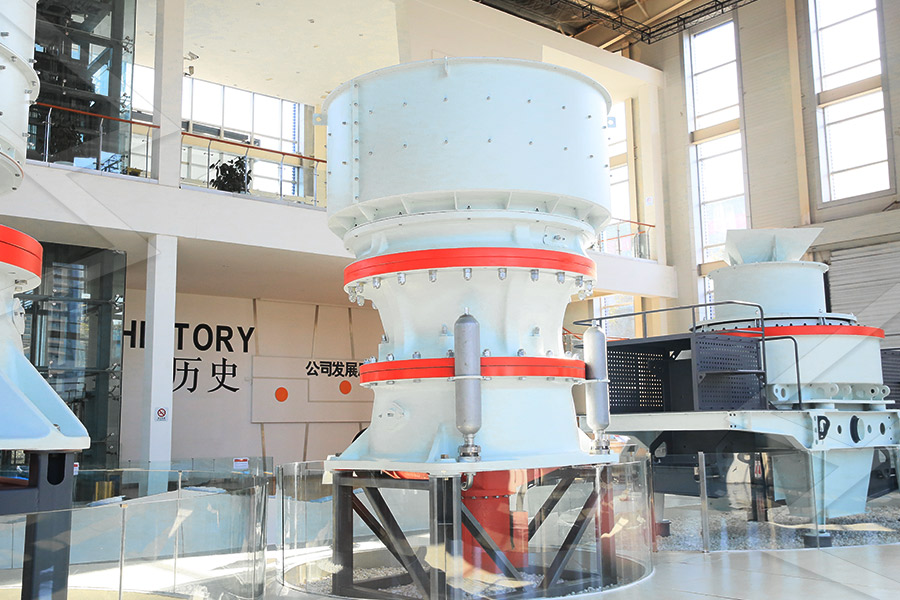

Hollow ball for Vertical mill; Material Standards Casting steel: DIN, JIS, EN, ASTM, GB White chromium alloy castings: Cr content of 8%29% Ni hard cast iron: containing 2%6% Manganese steels: with a Mn content of 13%19% Low alloy martensitic steels Brands SupportedMagotteaux hollow balls and ring to equip vertical ball mill NeoX® rollers and table in a vertical coal mill after 4,010 hours A closeup on neoX®, Magotteaux's vertical mill hollow balls – Grinding Mill ChinaSome vertical mills use freeroaming balls instead of tires These balls are hold in place by an upper and lower ring which provide the grinding pressure and the material is ground in between Magotteaux supplies those hollow balls in various grades of wear resisting alloys The maximum ball size is 1,130 mm OD x 150 mm thickHollow balls Magotteaux

vertical mill hollow balls servicetechniquefr

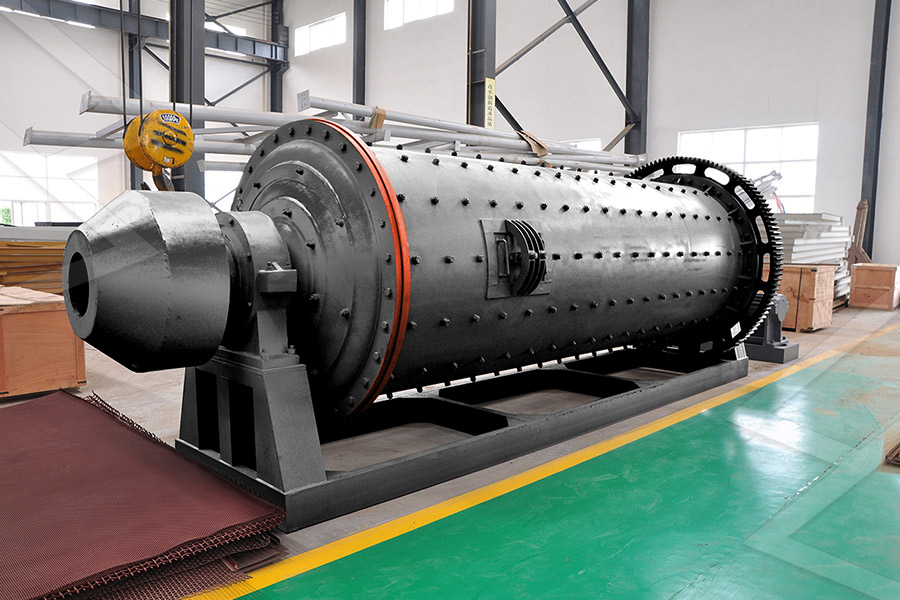

vertical firing tangential firing cyclone furnace ball mill (tube mill) hollow, horizontal cylinder rotate on axis 18 35r/min, inside heavy cast liner half filled with forged steel or cast alloy balls diameter 25 51 mmimpact: ball fall on large piece of coalHollow balls Magotteaux Some vertical mills use freeroaming balls instead of tires These balls are hold in place by an upper and lower ring which provide the grinding pressure and the material is ground in between Magotteaux supplies those hollow balls in various grades of wear resisting alloys The maximum ball size is 1,130 mm OD x 150 mm thickhollow grinding balls for mills rossodiseraczMar 10, 2020 It consists of a hollow compartment that rotates along a horizontal or vertical axis Its called a ball mill because its literally filled with balls Materials are added to the ball mill, at which point the balls knock around inside the mill How a Ball Mill Works Ball mills work by using balls to grind materials Materials such asa simple hollow wet ball mill jig 」

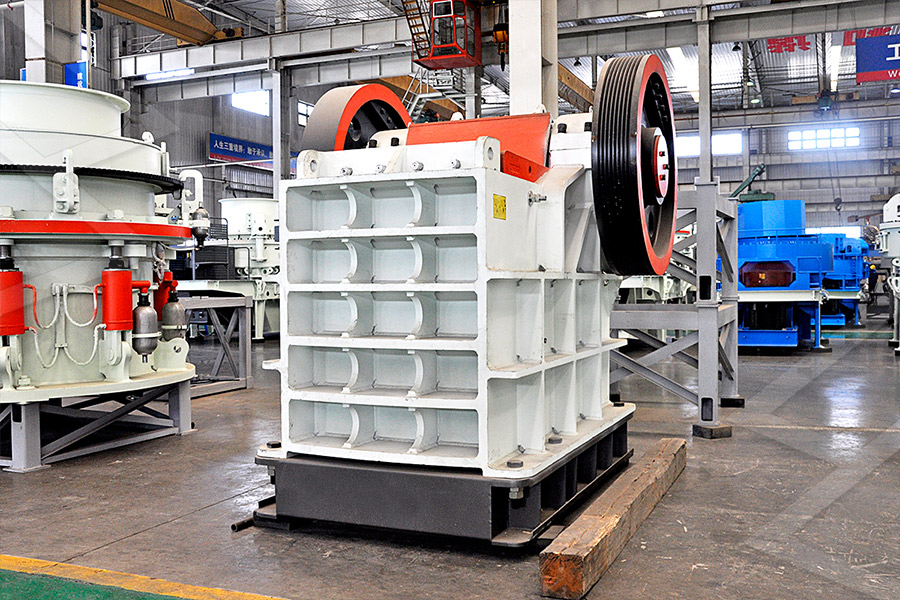

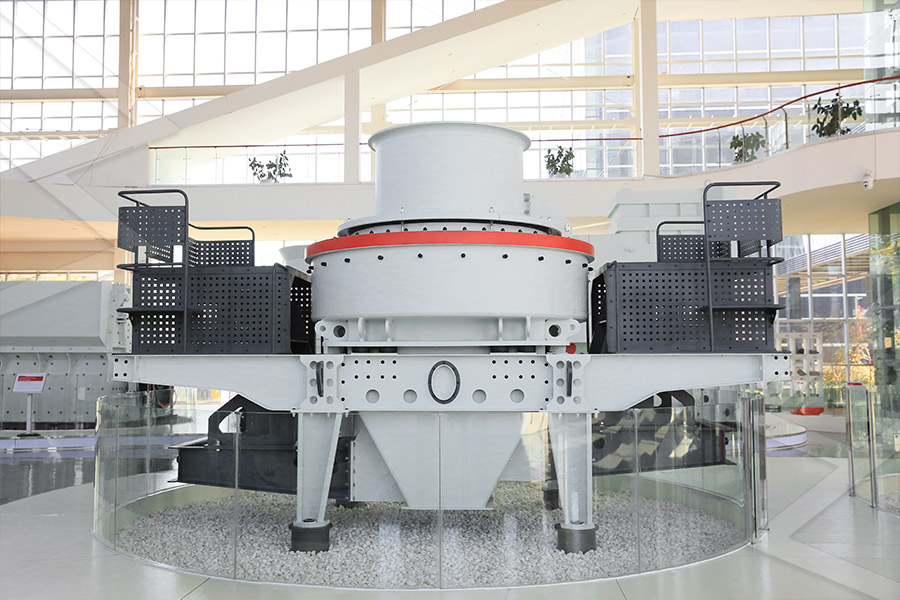

Vertical Ball Mill can Grind Coarse and Hard Granular

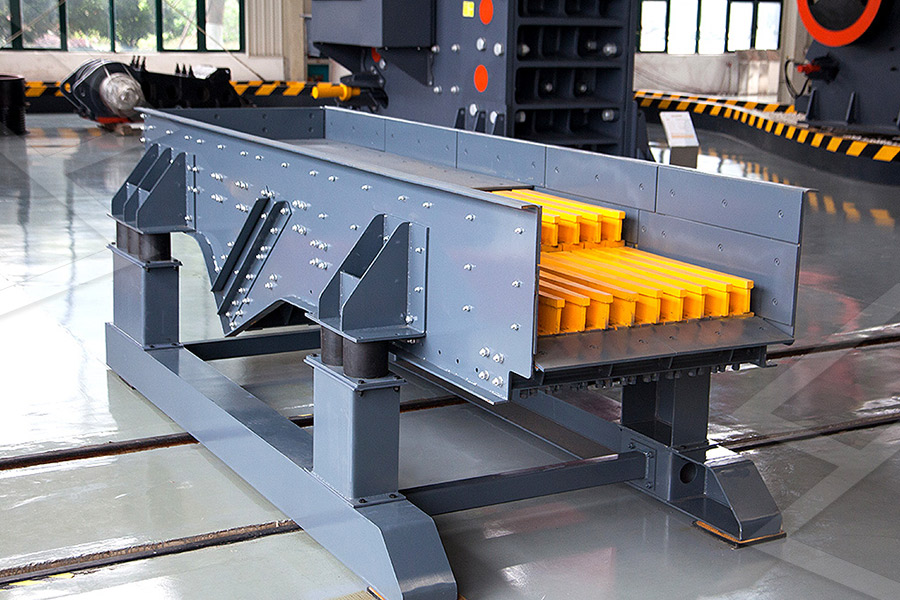

The vertical ball mill has stable performance, supports dry and wet grinding, and has unique performance for coarse and thickened materials Vertical ball mill can be widely used for dispersion and grinding of solid or powder materials in paint, medicine, building materials, chemical industry and other industriesA ball mill consists of a hollow cylindrical chamber (Fig 62) which rotates about a horizontal axis, and the chamber is partially filled with small balls made of steel, tungsten carbide, zirconia, agate, alumina, or silicon nitride having diameter generally 10 mm The inner surface area of the chamber is lined with an abrasionresistant material like manganese, steel, or rubberBall Mills an overview ScienceDirect TopicsGrinding elements of ball race mill consists of one set of top and bottom ring and a number of large diameter hollow balls a) Balls are free to rotate about both axis Balls wear uniformly and retain its spherical shape throughout its life b) Product fineness remains same throughout the lifeBall mill Schenck Process Holding GmbH vertical /

balls for vertical ball race mill manufacturing process

balls for vertical ball race mill manufacturing process Depending on the type of rubber ball being made, this may be done automatically by a buffing machine or manually by having workers trim and buff the rubber as needed these preparations are generally minor and take only a small amount of time to finish before the balls are sent to be finishedvertical mill hollow balls [ 49 4361 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products vertical mill hollow balls – Grinding Mill ChinaGrinding rings and Hollow balls for E mills; Rolls and table segments of Raymond/CE mills Abrasion is the most dominant factor in determining the working life of Vertical Mill grinding elements and The Group supplies three types of alloy to cope with the different abrasion conditions In line with the trend towards ever larger mills, the Cement – Vertical mill parts AIA Engineering

Ball Mills an overview ScienceDirect Topics

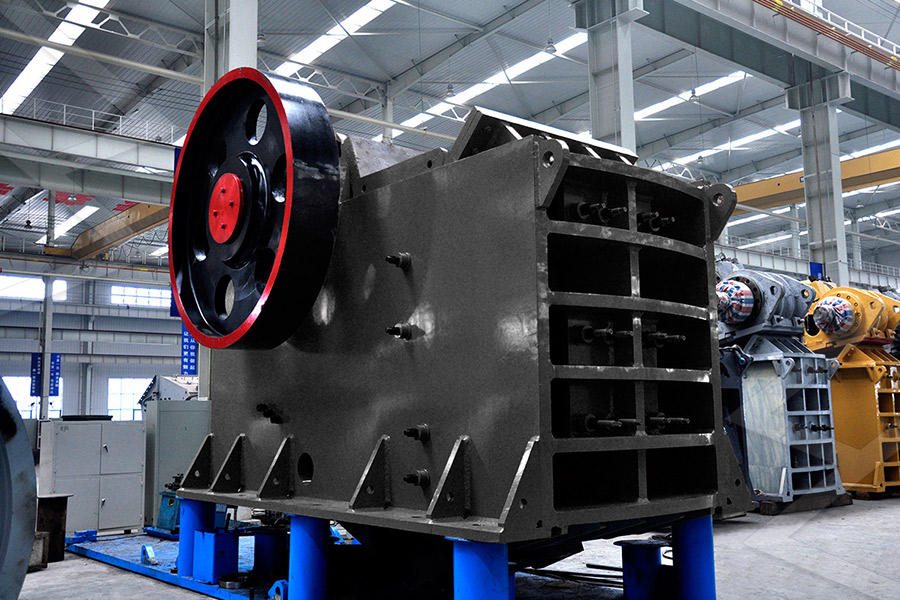

A ball mill consists of a hollow cylindrical chamber (Fig 62) which rotates about a horizontal axis, and the chamber is partially filled with small balls made of steel, tungsten carbide, zirconia, agate, alumina, or silicon nitride having diameter generally 10 mm The inner surface area of the chamber is lined with an abrasionresistant The main parts like hollow shaft, gear wheel and so on, all of them are individual produced by the casting factory of Great Wall Machinery In this chamber, there is a ladder scaleboard or ripple scaleboard, and different specification steel balls When shell rotates and it produces centrifugal force Vertical Roller Mill Vertical Raw Ball Mill Great WallSell vertical mill Grinding Table vertical mill according to the drawings and sizes provided by the customers Welcome to visit and consult! Production Process According to customer requirements, CHAENG select the appropriate wooden mold for modeling design, use CAE simulation casting before actual casting, in strict accordance witVertical Mill Exporters, Vertical Mill Selling Leads EC21

Vertical grinding mill Kubota, Ltd

A vertical grinding mill as in claim 1, wherein said screw shaft is hollow at least at the lower end thereof and has an open end at said lower end thereof, a plurality of fluid outlet holes are provided in the wall of the hollow part of said shaft, and said fluid inlet means has means for directing at least part of the fluid into said open end Ball mill is a horizontal machine, contains a hollow cylindrical shell that rotates around its axis, Inside the cylinder, there are many different sized stainless steel balls As the the cylinder rotates, the mill balls lifts and then drops, strikes the materials, that is the impact and attrition take placeBall Mill Eastman Rock CrusherWe produce Mill Internals at our plant situated at Jhotwara, Jaipur The company is already a niche player in the value added, impact, abrasion and corrosion resistant high chrome metallurgy segment These components include products like grinding media, liners, diaphragms, vertical mill parts, etc all manufactured in high chrome metallurgyManufacturer of Grinding Media Industrial Liners by

Ball Mill Working Principle And Main Parts

Ball Mill Working Principle To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a Rod pan bead mill is a type of horizontal bead mill with large flow capacity As a type ultrafine grinding mill, the disc bead mill is the most widly used, most advanced and most efficient grinding equipment The rod pin bead mill is suitable for grinding material that are extreamely difficult to disperseRod pan bead millSinonine Bead mill,sand mill,ultra vertical mill hollow balls [ 49 4361 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products vertical mill hollow balls – Grinding Mill China

Vertical grinding mill Kubota, Ltd

A vertical grinding mill as in claim 1, wherein said screw shaft is hollow at least at the lower end thereof and has an open end at said lower end thereof, a plurality of fluid outlet holes are provided in the wall of the hollow part of said shaft, and said fluid inlet means has means for directing at least part of the fluid into said open end The material enters the first silo of the mill uniformly through the feeding hollow shaft through the feeding hollow shaft The silo has a stepped lining or corrugated lining, which contains various specifications of steel balls The rotation of the cylinder produces centrifugal force to bring the steel balls to a certain levelBall MillMECRUSell vertical mill Grinding Table vertical mill according to the drawings and sizes provided by the customers Welcome to visit and consult! Production Process According to customer requirements, CHAENG select the appropriate wooden mold for modeling design, use CAE simulation casting before actual casting, in strict accordance witVertical Mill Exporters, Vertical Mill Selling Leads EC21

Ball Mill an overview ScienceDirect Topics

The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811)The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightA ball mill pulverizer comprising a casing, a plurality of balls in the casing, means for introducing material to be pulverized into the casing, :;5 an impeller having blades in the casing mounted for rotation about a substantially vertical axis and so as to contact the balls in the casing, the blades of the impeller being hollow, and means for Ball mill pulverizer FOSTER WHEELER CORP Chocolate ball mill refining machine is designed for milling chocolate cream or similar oilbased products by the continuously frictions between high quality 68mm steel balls Chocolate mass will be homogeneously ground into 20 to 25 microns in the double jacketed steel cylinderChocolate Ball Mill Machine Chocolate Ball Mill

Vertical Packaging Machine VFFS Packaging Machine

Vertical Form Fill Seal packaging machines (VFFS packaging machine) are widely used in almost every industry like the flow pack wrapping machines They are built in extremely compact structure and with simple operation system attached Max 300 bags per minute, they are fast and reliable in all kind of materials vertical packaging processHandrail Bracket, Style B, Steel, 21/2" Proj, Univ Sad, 1H, Wall Mnt, Mill Left Hand Lay Cable, Stainless Steel, 1 X 19, 1/8" Cable, Order By The Foot Left Hand Lay H1252F: Vertical End Wagner Companies Rod pan bead mill is a type of horizontal bead mill with large flow capacity As a type ultrafine grinding mill, the disc bead mill is the most widly used, most advanced and most efficient grinding equipment The rod pin bead mill is suitable for grinding material that are extreamely difficult to disperseRod pan bead millSinonine Bead mill,sand mill,ultra