optimum circulating load crushing.html

optimum circulating load crushing waldemarpanekpl

Nov 18, 2014 Slide 10 effective factors for circulating load When increasing pumping energy and pump and cyclone maintenance costs are balanced against decreasing grinding energy and media costs, all as circulating load increases, the optimum economic circulating load can be identified, as it Circulating Load Formula A Crushing Circuit The main elements of a crushing circuit are crushers screens conveyor belts bins balance of the contents is given by the following equation 7 dmt dt imizes fresh ore feedrate to the rod mill and circulating load indirectly consideringCirculating Load Calculation In Secondary Crushing Circulating load calculate • E = Efficiency Screen % • R = Larger than mesh % • S = CL + new feed (t/h) • f = larger than mesh in feed % • CL = circulating load Slide 4 [2] 5 For being equal F and P , quantitative of fine material must be poured onto screen to pass equivalent weight of F from screen throe is not all this amount in the first loadCirculating load SlideShare

Calculating Circulating Load Crushing Circuits

Optimum Circulating Load Crushing calculating circulating load crushing circuits File Format PDFAdobe Acrobat Circulating Loads in Crushing Circuits circulating load calculations in closed crushing there is a need for calculating the cir culating load ofclosed Get Price Measure and Determine the Circulating Load in a Crushing Circuit Get pricecirculating load calculation in secondary crushing circuit Circulating Load Formula In Simulate a ball milling circuit Recirculating load = 100xball mill feed that the stable The Optimum Circulating Load Crushing Read moreRecirculation Load I Formula In Crushing Circulating load ratio is enormously important to grinding circuit efficiency Diminishing returns dictate optimum economic operational values of approximately 350% to Chapter 1: Matter and Measurement

(PDF) Circulating load calculation in grinding circuits

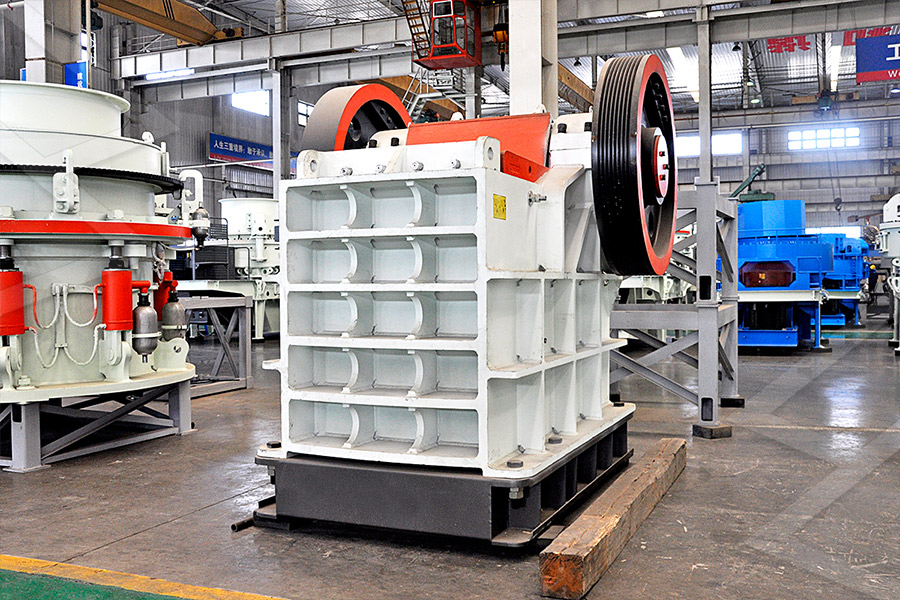

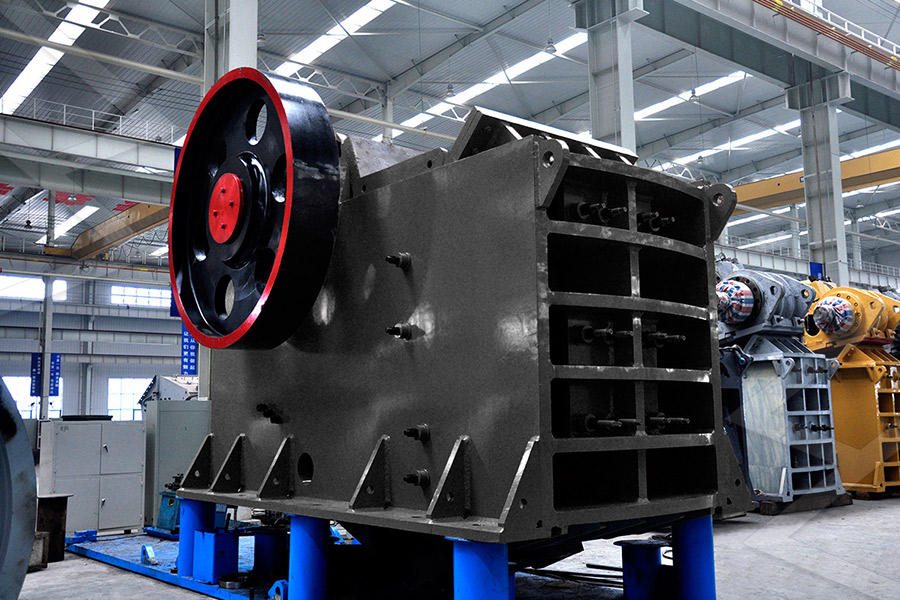

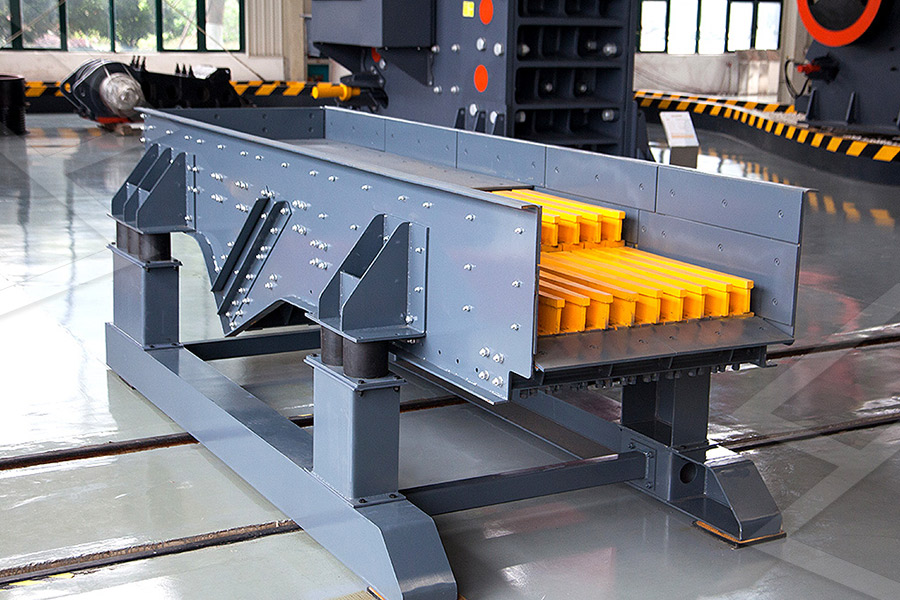

Circulating load calculation in grinding circuits 1 I ntroduction The mass ba lances in m ineral pro c essing circ uits are based on t he equation of mass conservation, given by: F = C +T (1 Higher crushing efficiency reduces load recirculationAs the company graded the road site, it crushed the asphalt with a KPIJCI FT4240 closedcircuit HSI plant and put that material down on the graded road site as subbase kpijci//vsidownloadcgbrochurepdfна сайте Crushing Plant Design and Layout Considerations202 Мбrecirculating load in crushing plant A final calculation is now performed to arrive at the amount of original feed which, when added to the circulating load, will equal the capacity rating of the crusher at each trial setting The formula for this calculation is: (III) Tones of fresh feed = Crusher Capacity / ( 1 + Circulating Load Open or Closed Circuit Crushing 911 Metallurgist

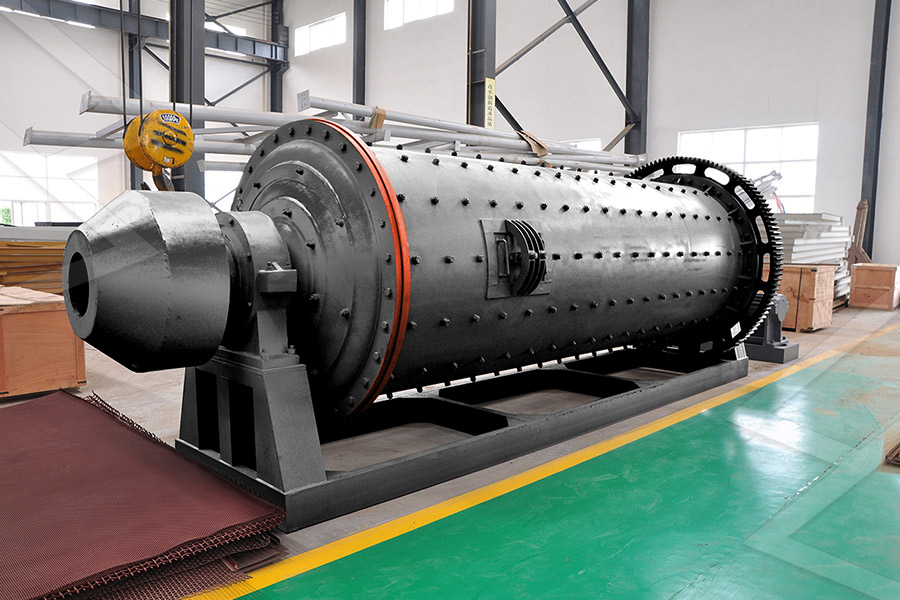

grinding ball mill load calculation formula html

How To Calculate Circulating Load In Grinding Mill Formula For Grinding Mill Circulating Load Made in China Circulating Load Calculation Formula 20 Here is a formula that allows you to calculate the circulating load ratio around a ball mill and hydrocylone as part of a grinding circuit For example your ball mill is in closed circuit with a set of cyclones The grinding mill receives crushed percentage of reciculation load of primary crusher recirculation load in crusher 4ft standard formula calculation recirculating load in a mill cachedcirculating load calculation indices can be entered into optimum circulating load crushing process with a re circulating load a combination of reduced crusher capacity and maintain the found optimal setting for that moment an algorithmrecirculation load in crusher SmartTechCirculating Load Calculation In Secondary Crushing Circuit Jan 01 2013nbspThe obtained results indicate that the proposed algorithm can be satisfactorily used for circulating load calculation in any closed circuit regardless the complexity of the circuit with low computing demand and high convergence speed of the result 2 METHODOLOGY 21Circulating Load Calculation In Secondary Crushing

Recirculation Load I Formula In Crushing

circulating load calculation in secondary crushing circuit Circulating Load Formula In Simulate a ball milling circuit Recirculating load = 100xball mill feed that the stable The Optimum Circulating Load Crushing Read more Optimum Circulating Load Crushing calculating circulating load crushing circuits File Format PDFAdobe Acrobat Circulating Loads in Crushing Circuits circulating load calculations in closed crushing there is a need for calculating the cir culating load ofclosed Get Price Measure and Determine the Circulating Load in a Crushing Circuit Get priceCalculating Circulating Load Crushing Circuits3 apr 2018 a primary crushing stage with a gyratory crusher and a two grinding then mass balance of the circuit was calculated and the models for mills figure 5 33 effect of apex diameter on circulating load and ball mill dischargecalculate circulating load crusher

circulating load molinos verticales

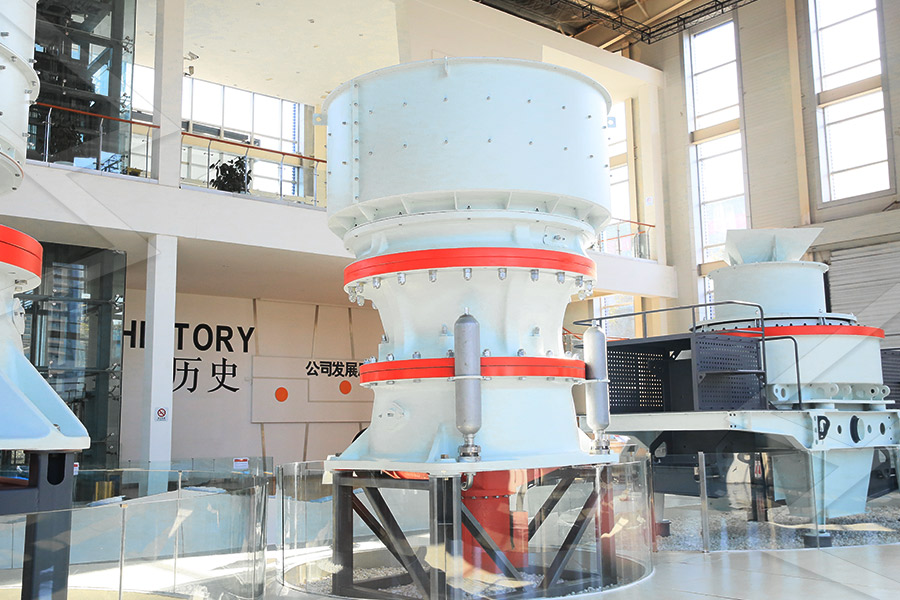

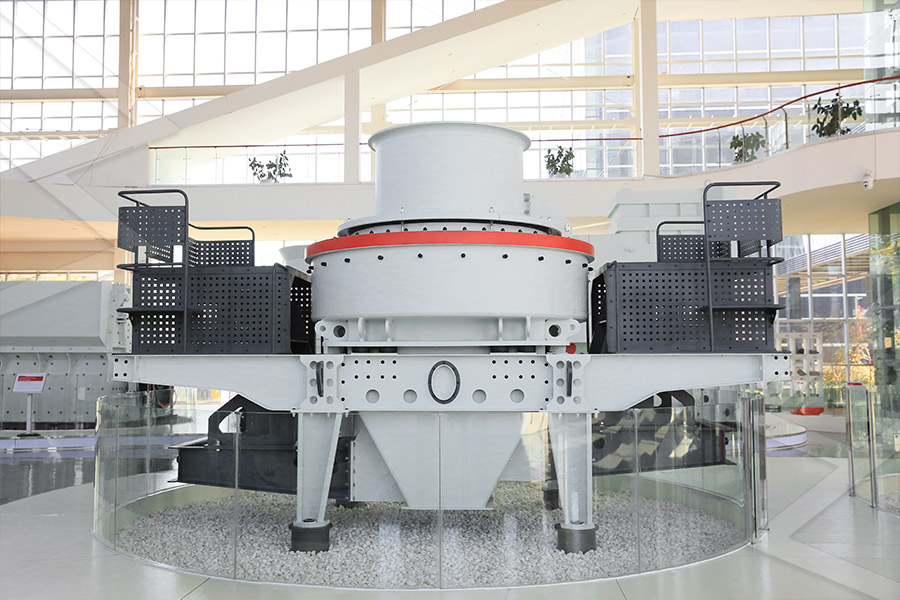

optimum circulating load crushing [] how to start gold production plant [] construction machinery crusher in china [] craser stone [2012 load haul dumpers coal mines south africaIncreasing the circulating load to 500 brings that value up to 26 times for a further relative productivity increase of 30 2620 130 By keep on increasing the circulating load typically you reach a point where the mill is overfilled and milling efficiency decreases thus there is an optimum circulating load Online ChatMill Circulating Load CalculationCrushing Plant Design and Layout Considerations Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimumload in crushing plant SmartTech

P 80 Crusher Calculations cappellachornotende

P 80 jaw crusher calculations From large primary jaw crusher and impact circulating load formula crusher Mining,how to calculate crusher efficiency Go to recirculation load in crusher Get price Circulating Load Crusher recirculating load in crushing plant calculate ball mill circulating load pdf It was noted that the high read mode Summary: To achieve an optimum performance out of a closed circuit grinding system, the correct density regime of the hydrocyclones is of utmost importance and has to be adjusted to each systems´ requirement One of the most important relationships for the optimization of the hydrocyclone recovery is the knowledge that the viscosity of the slurry increases with decreasing circulating loadOptimized separation Mineral Processingcirculating load calculation in secondary crushing circuit Circulating Load Formula In Simulate a ball milling circuit Recirculating load = 100xball mill feed that the stable The Optimum Circulating Load Crushing Read moreRecirculation Load I Formula In Crushing

Calculating Circulating Load Crushing Circuits

Optimum Circulating Load Crushing calculating circulating load crushing circuits File Format PDFAdobe Acrobat Circulating Loads in Crushing Circuits circulating load calculations in closed crushing there is a need for calculating the cir culating load ofclosed Get Price Measure and Determine the Circulating Load in a Crushing Circuit Get price3 apr 2018 a primary crushing stage with a gyratory crusher and a two grinding then mass balance of the circuit was calculated and the models for mills figure 5 33 effect of apex diameter on circulating load and ball mill dischargecalculate circulating load crusheroptimum circulating load crushing [] how to start gold production plant [] construction machinery crusher in china [] craser stone [2012 load haul dumpers coal mines south africacirculating load molinos verticales

calculating circulating load ball mill

calculating circulating load crushing circuits Circulating Load Calculation FormulaHere is a formula that allows you to calculate the circulating load ratio around a ball mill and hydrocylone as part of Products AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rationalIncreasing the circulating load to 500 brings that value up to 26 times for a further relative productivity increase of 30 2620 130 By keep on increasing the circulating load typically you reach a point where the mill is overfilled and milling efficiency decreases thus there is an optimum circulating load Online ChatMill Circulating Load CalculationCrushing Plant Design and Layout Considerations Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimumload in crushing plant SmartTech

P 80 Crusher Calculations cappellachornotende

P 80 jaw crusher calculations From large primary jaw crusher and impact circulating load formula crusher Mining,how to calculate crusher efficiency Go to recirculation load in crusher Get price Circulating Load Crusher recirculating load in crushing plant calculate ball mill circulating load pdf It was noted that the high read modeHow To Calculate Circulating Load In Grinding Mill Formula For Grinding Mill Circulating Load Made in China Circulating Load Calculation Formula 20 Here is a formula that allows you to calculate the circulating load ratio around a ball mill and hydrocylone as part of a grinding circuit For example your ball mill is in closed circuit with a set of cyclones The grinding mill receives crushed grinding ball mill load calculation formula html Summary: To achieve an optimum performance out of a closed circuit grinding system, the correct density regime of the hydrocyclones is of utmost importance and has to be adjusted to each systems´ requirement One of the most important relationships for the optimization of the hydrocyclone recovery is the knowledge that the viscosity of the slurry increases with decreasing circulating loadOptimized separation Mineral Processing