How To Clean A Jaw Crusher

How to clean the jaw crusherJiaozuo zhongxin heavy

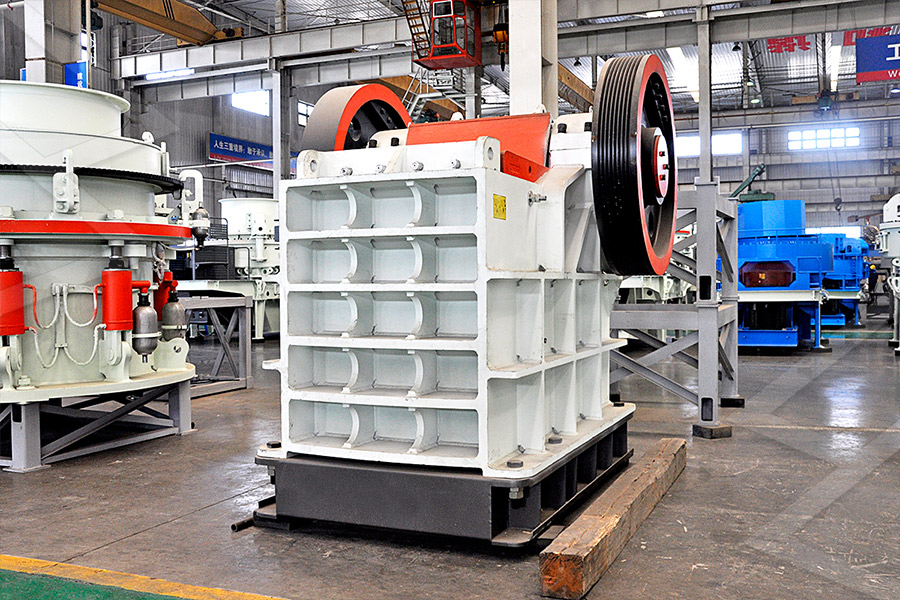

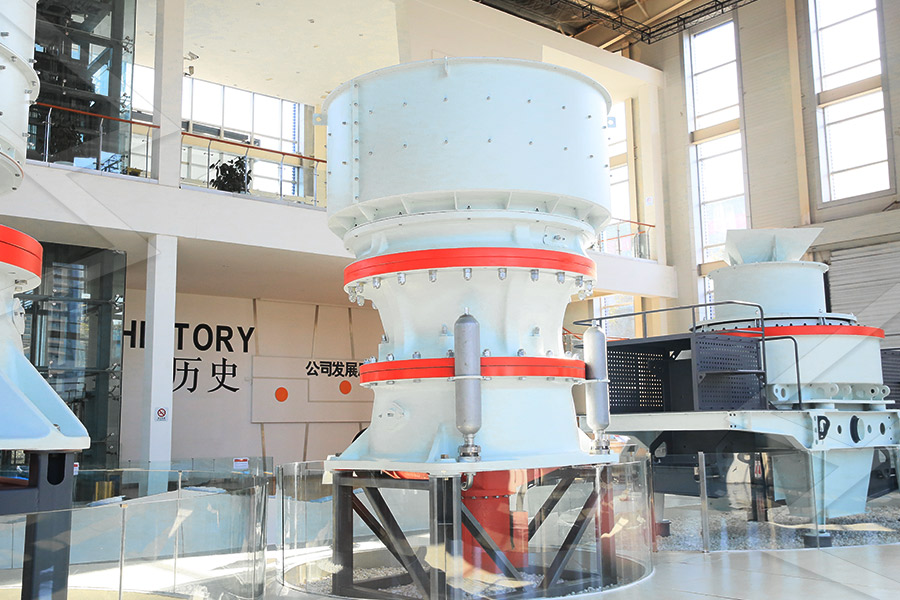

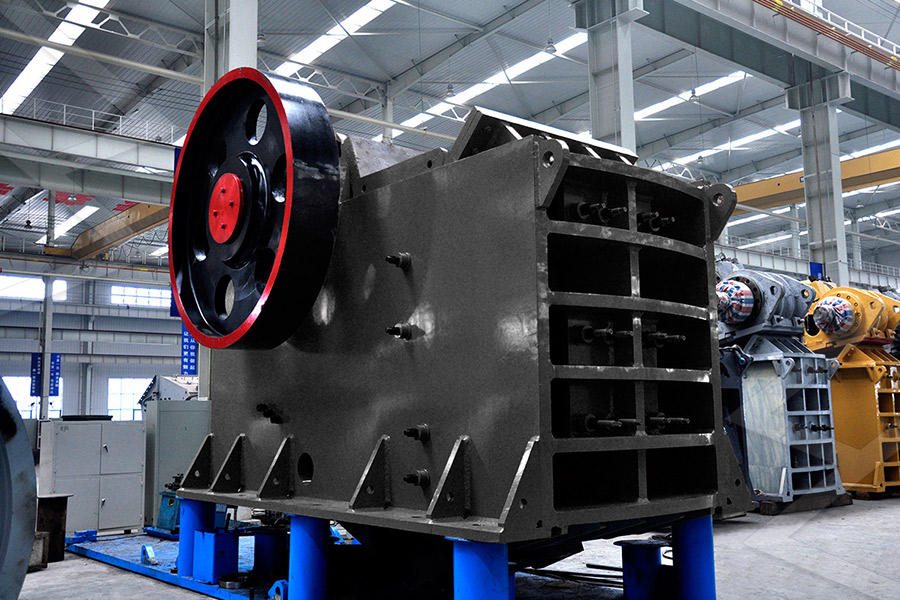

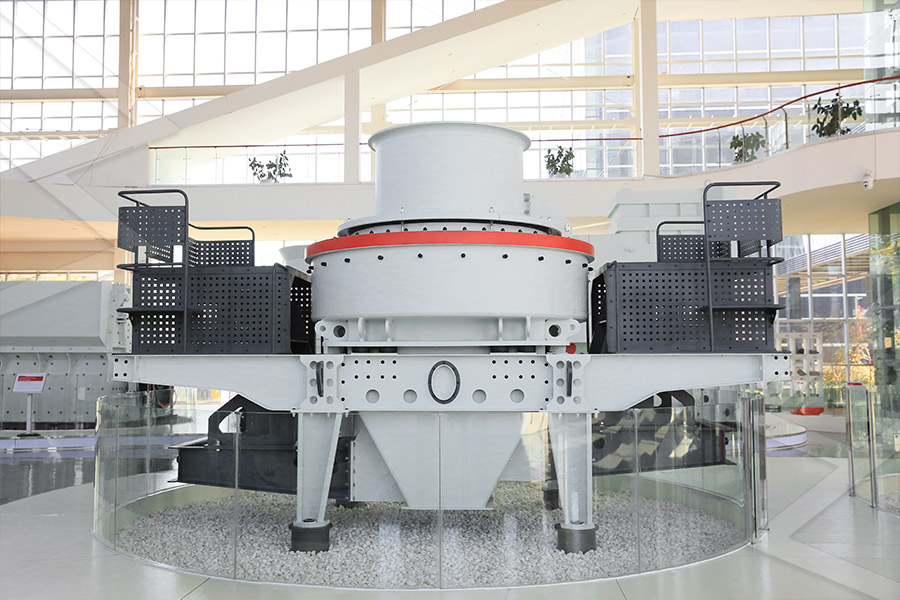

Jaw crusher is a commonly used mechanical equipment for ore crushing and processing Unlike ordinary ore crushers, the jaw crusher has a relatively large crushing force and can be used for granite, dolomite, calcite and other highhardness ores Crushers are generally used for coarse crushing operations in sand and gravel production lines, and have a very wide range of applicationsJaw Crusher Clean Jaw crusher clean for each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more quicklyHow To Clean A Jaw Crusher anigohbdeHow To Clean A Mining Jaw Stone Crusher Armenia how to clean a Mining jaw stone crusher Armenia Jaw crusher Jaw crusher is widely used in crushing the medium particle size materials of varieties of minerals and large materials, and it is widely used in mining, smelting, building material, highway, railway, water conservancy and chemical How To Clean A Jaw Crusher nervensonographiech

How to maintain jaw crusher Sanme

Clean oil or kerosene should be used to clean the roller bearing raceway when changing oil (4) Before starting the jaw crusher, an appropriate amount of grease should be injected between the thrust plate and the thrust plate support Maintenance of jaw crusher Crusher is a commonly used crushing equipment After using the machine, the correct inspection and maintenance must be done In the actual production process, many customers do not pay attention to the cleaning of the crusher when they use it, but if they do not clean it, it will affect the operation of the crusher equipment and expand the maintenance cost of the equipmentHow to clean the Crusher correctly? Luoyang Dahua “Successful jaw crusher maintenance requires the right resources, the right tools and the right approach,” says Bill Macini, a Telsmith service technician Jaw crusher maintenance : Pit Quarry

The Most Practical Jaw Crusher Repair and

a template of jaw crusher checklist 2Do the lubrication job well The lubrication of the interface between the parts of the jaw crusher is very important It can minimize the friction generated during the operation, make the whole jaw crusher run smoothly, and extend its service life Repair of jaw crusher There is inevitable come with fault, in addition to the correct operation of the jaw crusher, scheduled maintenance and repair must be carried out Minor repairs including conventional checking drive system, lubricating system, and adjust jaw Maintenance and Repair of Jaw Crusher JXSC MineCrusher Types Jaw Crushers Jaw crushers operate by squeezing rock between two surfaces, one of which opens and closes like a jaw Rock enters the jaw crusher from the top Pieces of rock, that are larger than the opening at the bottom of the jaw, lodge between the two metal plates of the jaw The opening and closing action of the movable jaw Clearing Blocked Crushers Health and Safety Authority

5 Tips Help you Operate Jaw Crusher Easily MC

5 Check the wear of jaw plate and transmission parts, whether there are cracks in the pull rod spring and whether the work is normal 6 Keep the jaw crusher clean, prevent Crusher is a commonly used crushing equipment After using the machine, the correct inspection and maintenance must be done In the actual production process, many customers do not pay attention to the cleaning of the crusher when they use it, but if they do not clean it, it will affect the operation of the crusher equipment and expand the maintenance cost of the equipmentHow to clean the Crusher correctly? Luoyang Dahua Jaw Crushers Check oil regularly, making sure it is free of dirt and contaminants Check jaw dies every day, and make sure bolts are fastened securely Maintain crusher backing to ensure proper vibration and impact protection Keep breathers clean Make sure the toggle area is clean, especially prior to any adjustments Wash out seats and Tips for Crusher Maintenance Thomasnet

How effective maintenance of jaw crusher?

Question:How effective maintenance of jaw crusher? Asker:admin Hits: Detail:How effective maintenance of jaw crusher? This is the user to buy, buy later will ask the question, is crucial for future use, because the use of scientific and reasonable method of jaw crusher and maintenance can not only prolong the life of the crusher can also improve production efficiencyjaw crusher Overview It is well known that jaw crusher is the most commonly used primary crushing equipment in crushing plants In the operation process of jaw crusher, investors generally pay attention to the crushing efficiency, crushing ratio, and some other factorsJaw Crusher Maintenance Gravel Mill [2] jaw crusher used lubricating grease should be based on the location of use, the temperature conditions may be, under normal circumstances using calcium, sodium and calcium sodium based grease [3] adding grease within the bearing for about 50% of volume of space, every 3 to 6 months to replace aJaw crusher lubrication

Jaw Crusher Operation And MaintenanceJiaozuo zhongxin

Jaw Crusher Operation And Maintenance 14:45:25 The prepare working before crusher startup: Checkup the lubricate of axletree;knee plate and adjust the contact of knee plate’ mat,it’s have enough lube between keen plate mat or not Adjust all fastener fiemlyCrusher Types Jaw Crushers Jaw crushers operate by squeezing rock between two surfaces, one of which opens and closes like a jaw Rock enters the jaw crusher from the top Pieces of rock, that are larger than the opening at the bottom of the jaw, lodge between the two metal plates of the jaw The opening and closing action of the movable jaw Clearing Blocked Crushers Health and Safety Authority 1 Fill the lower ore bin with ores Before the crusher stops, remove unstable ores at the ore outlet after the heavy plate feeder stops to prevent them from falling during construction 2 Stop the crusher after breaking the mine, and clean the slag around the wedge block, wedge fixing bolt and jaw plate hoisting hole with the sweeperSteps for Removing the Jaw Plate of the Jaw Crusher

Jaw Crusher china

Jaw crusher has been widely applied in mining, metallurgical, construction, road and railway building, water conservancy and chemistry etc It is mainly applied in the primary crushing in which the compressive strength of original material is under 320Mpa Jaw crusher is one of the most widely used crushing equipment in mining industryVery Clean Jaw Crusher for sale Cheap Mobile Jaw Crusher for sale The compact design 19Ton crusher has a big attitude and it is pacifically designed to deal with the day to day crushing of recycled materials eg Bricks, Blocks, Slabs including hard rock applications and concrete The Nordmann T750 Jaw Crusher is ideal for working inside Nordmann T750 Jaw Crusher for sale, used small jaw The methods about how to clean the jaw crusherSanme Put jaw crusher’s spare parts into the container spray sprays on the surface of the spare parts and clean Shanghai SANME thinks this one way to clean jaw crushers spare parts

How to maintenance jaw crusher properly baichy

Successful jaw crusher maintenance requires the right resources, the right tools and the right method When an operation is down, whether for preventive maintenance or component failure, there is always the pressure to get the plant up and running as soon as possible Here are main steps for jaw crusher maintenace Firstly, Cleanliness is key Question:How effective maintenance of jaw crusher? Asker:admin Hits: Detail:How effective maintenance of jaw crusher? This is the user to buy, buy later will ask the question, is crucial for future use, because the use of scientific and reasonable method of jaw crusher and maintenance can not only prolong the life of the crusher can also improve production efficiencyHow effective maintenance of jaw crusher? MAINTENANCE OF JAW CRUSHER 1 In order to guarantee normal operation of machine and prolong service life, inject lubrication oil is needed regularly 2 About 50% to 70% of volume of all bearing housings should be filled with grease Change the grease each 36 month, clean the roller bearing carefully 3MAINTENANCE OF JAW CRUSHERLiming Heavy

The Most Practical Jaw Crusher Repair and

a template of jaw crusher checklist 2Do the lubrication job well The lubrication of the interface between the parts of the jaw crusher is very important It can minimize the friction generated during the operation, make the whole jaw crusher run smoothly, and extend its service life Repair of jaw crusher There is inevitable come with fault, in addition to the correct operation of the jaw crusher, scheduled maintenance and repair must be carried out Minor repairs including conventional checking drive system, lubricating system, and adjust jaw plates, replace wear parts The period about 13 monthsMaintenance and Repair of Jaw Crusher JXSC Mineclean jaw crusher Our leading products have crushing equipment, sand making equipment, mobile crusher,jaw crusher,stone crusher ,cone crusher etc tips help you operate jaw crusher easily m amp c,keep the jaw crusher clean prevent sundries from entering the lubrication system to accelerate the wear of the equipment and shorten the life of the equipment clean the filter of lubricating oil clean jaw crusher wonderavenues

Summary of Jaw crusher removing method and the

The correct method of operation to disassemble jaw crusher is for connecting rod is broken confidential overall remove the thrust plate, screw out the first baffle bolt, cut off the lubricating oil pipe, the thrust plate is hung on the crane hook or other lifting equipment, and then spring to release a horizontal connecting rod, the movable jaw Jaw crusher has been widely applied in mining, metallurgical, construction, road and railway building, water conservancy and chemistry etc It is mainly applied in the primary crushing in which the compressive strength of original material is under 320Mpa Jaw crusher is one of the most widely used crushing equipment in mining industryJaw Crusher chinaLITech is a member of the ASCO Group International: Leading solutions for steel construction, machinery and plant engineering and environmental technology The ASCO Group International is a corporate family with a focus on steel construction, machinery and plant engineering and environmental technology, which was founded in 1997Jaw crusher for efficient size reduction – LITech GmbH