electrical drive for ball Mill in cement plant

Central Drive Ball Mill In Cement Plants angle grinder

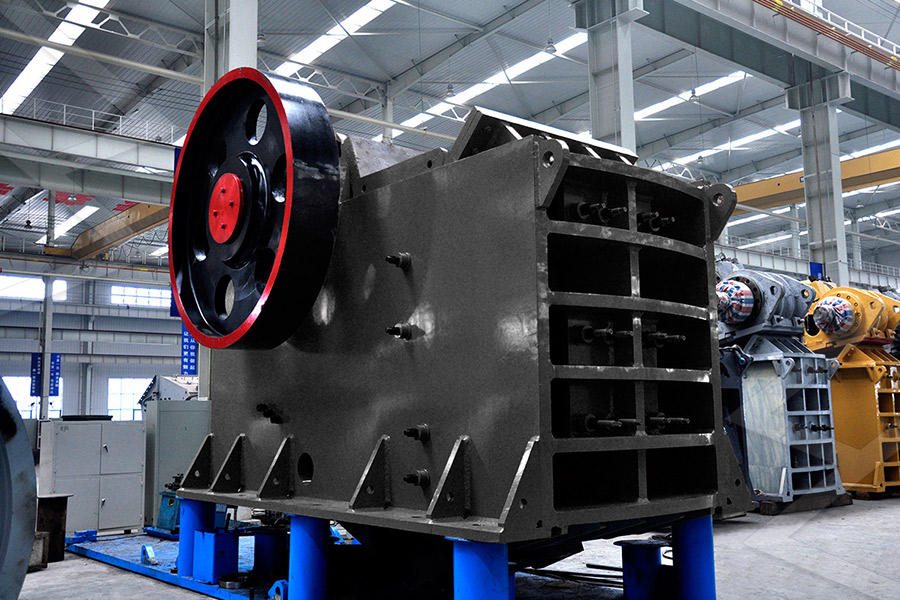

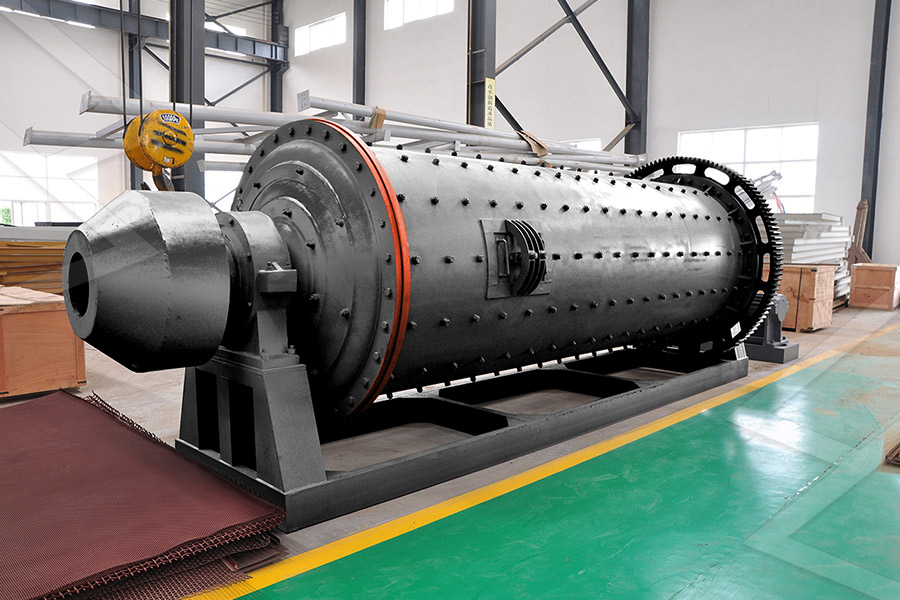

electrical drive for ball mill in cement plant electrical drive for ball mill in cement plant Cement Plant Modernization Scope of work included the structural, mechanical and electrical construction for: 90 st/hr 5000 HP closed circuit ball mill, with associated clinker, additives, 3000 st/d five stage preheater, pre Center drive and side drive are two common drive modes for a ball mill Center drive grinding mill means the motor shaft extends along the axis of mill body while side drive has a motor located on the side of the mill and torque is transmitted via the large girth gear which is bolted on the flange of the mill body Materials are fed into the mill at a fixed flow rate along the shaftless Cement Ball Mill Function: A cement mill is a drive used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills Process: Raw materials are fed to the mill in right proportion with the help of weighfeedersCement Mill Drives Transmission (Mechanics) Engines

Selecting AC induction motors for cement plant

Selecting AC Induction Motors for Cement Plant Applications (on photo:3,500 kW ballmill drive for a cement plant in England via emzde) Although motors may appear to be the least complicated component in the specification of cement mill equipment, this article shall try to demonstrate that cement plant Drive Device Used for Rotary Kiln, Girth Gear Used in Cement Clinker Rotary Kiln, Pinion Used for Lime Kiln manufacturer / supplier in China, offering Girth Gear Used for Ball Mill/Rotary Kiln in Cement Plant, Tpy Cement Grinding Production Line / Clinker Grinding Mill Plant Facility, Rotary Kiln Equipment Spare Parts Carrying Roller Part Support Roller Shaft Part and so onGirth Gear Used for Ball Mill/Rotary Kiln in Cement Plant Inching drives in a cement plant have two possible applications that support the production of product The first of which is the heart of any cement plant, the kiln Based on their design, it is critical to keep the kiln in motion at all times when heated The inching drive for this application is designed to operate wheneverSelecting Inching Drives for Mill and Kiln Applications

Cement ABB

Electrical powertrain for heavy working machines, without subtitles (English mp4 Movie) Driving value Sophisticated ringgeared mill drives from ABB ABB Review article (English pdf Article) Success in Vietnam Total plant solution for the Cam Pha cement plant (English pdf Article) The ball mill motor power requirement calculated above as 1400 HP is the power that must be applied at the mill drive in order to grind the tonnage of feed from one size distribution The following shows how the size or select the matching mill required Ball Mill Design/Power Calculation 911 Metallurgist The selection of AC induction motors for cement mill applications, with reference to fan, kiln and vertical mill applications Cement plant applications present an immense matrix of application criteria to specify, design and build motors properly Operating conditions Basic motor specifications begin with determining the motor nameplate horsepower (hp) and revolutions per minute (rpm) TheseSelection of AC induction motors for cement plant

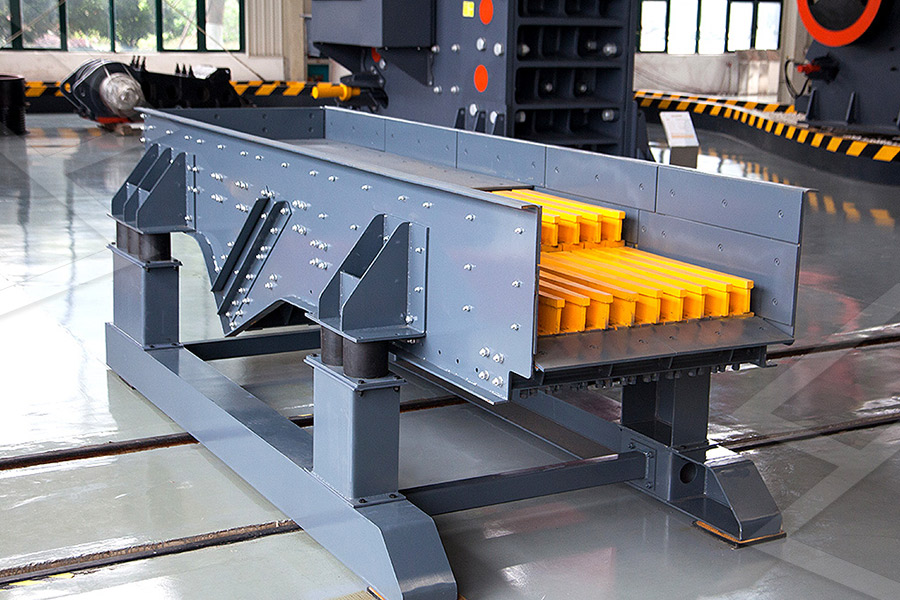

Cement Packing Machine Cement Equipment In

Cement packing machine is a kind of cement equipment which is necessary for the production of bagged cement It is mainly used to complete the automatic packing of cement and other powder materials with good fluidity, such as fly ash, gypsum powder, cement additives, etc Selecting AC Induction Motors for Cement Plant Applications (on photo:3,500 kW ballmill drive for a cement plant in England via emzde) Although motors may appear to be the least complicated component in the specification of cement mill equipment, this article shall try to demonstrate that cement plant applications present an immense matrix of Selecting AC induction motors for cement plant 5 Distribution System Within the Plant In a cement plant also there is a ‘mini grid‘ receiving power from main electricity grid and also from plant’s captive power plant They have to work simultaneously and hence should be ‘synchronized’ when working in parallel, ie, the voltage, frequency and phase must matchThe essentials of electrical systems in cement plants

Cement Mill Drives Transmission (Mechanics) Engines

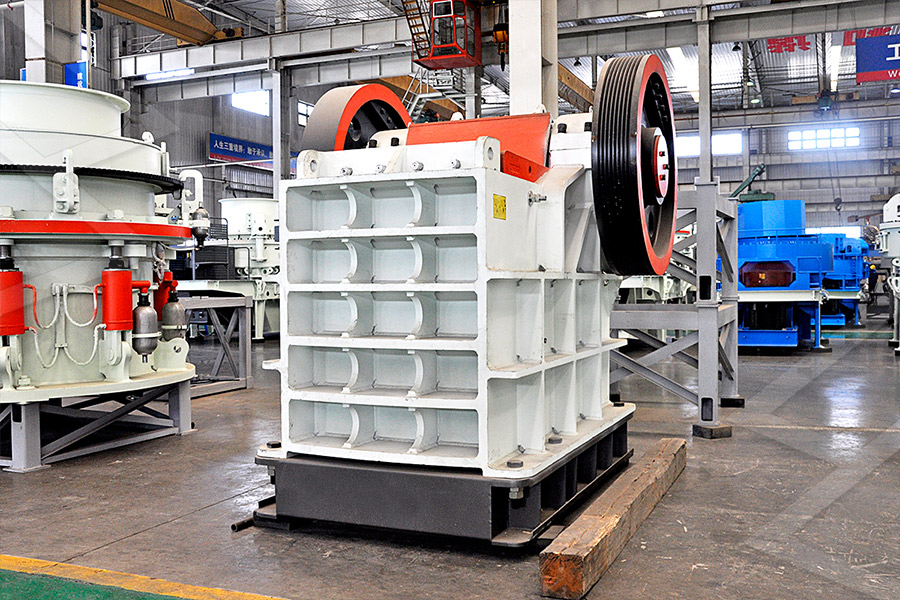

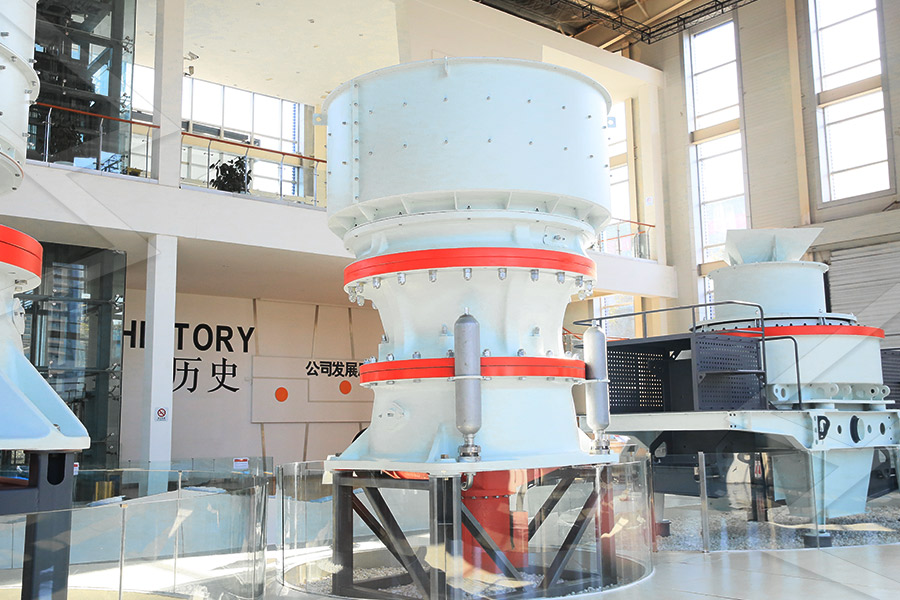

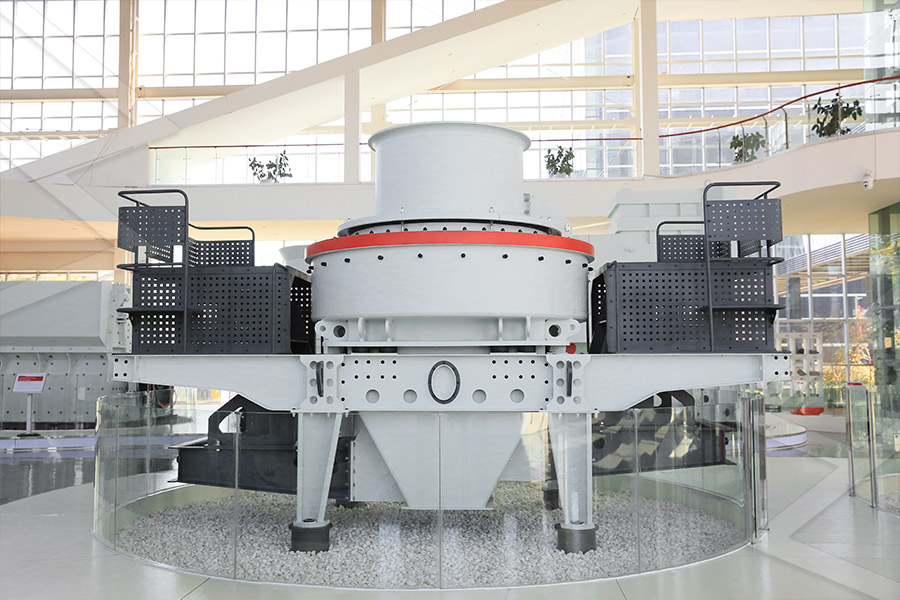

Function: A cement mill is a drive used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills Process: Raw materials are fed to the mill in right proportion with the help of weighfeeders the requirements The optimal drive type can only be selected after determining the mill size, the need for variable speed and the characteristics of the electrical system of the plant Comparison of Drives Systems for Grinding Applications The question what drive system is optimal for SAG and ball mills is project specific and depends on the TECHNICAL AND COMMERCIAL BENEFITS OF GEARLESS created by plant optimization and information technology ABB’s systems capabilities are essential tools for minimizing energy consumption and improve quality Drives Applications ABB manufactures motors and drive systems worldwide, from the subkilowatt to the megawatt ratings of the gearless drives for the largest SAG and ball mill applicaCement Plant Solutions for the Cement Industry

High Voltage Motors Manufacture EU VYBO Electric

Fan drive – Heating plant Humenné Electric motor 630kW H27R71010, 10pol, Y6000V, IM V1 Circulation pump drive Customer: power plant Vertical medium voltage motor 630kW Delivery of large 500kW and 630kW ring electric motors for 6000V system Application: ball mill drive Ball mill The selection of AC induction motors for cement mill applications, with reference to fan, kiln and vertical mill applications Cement plant applications present an immense matrix of application criteria to specify, design and build motors properly Operating conditions Basic motor specifications begin with determining the motor nameplate horsepower (hp) and revolutions per minute (rpm) TheseSelection of AC induction motors for cement plant The Cement Industry is moving in a constant area of tension between optimum quality, lower costs and shorter timetomarket Whether you are a plant operator, system integrator or plant and machine constructor: the solution to this problem is Totally Integrated Automation Advantages for plant ): Automation solutions for the Cement Industry

ACC Limited Jamul Cement Works Green Business Centre

mill and cement mill compressor to avoid unloading 9000 004 004 010 284 3 Reduced generation pressure and use cement mill 7 8 fluxo compressor only for conveying purpose 056 056 010 21 4 Minimised the compressed air leakages in the plant 074 074 010 16 5 Installed servo control voltage transformers for lighting and A Chinabased cement plant used VFDs to significantly reduce its energy consumption in its dryprocess kilns, responsible for production of 14 million tons of cement each year Traditional damper control systems used a fixed amount of energy, so fans at the plant always ran at full capacity even when the facility wasn’t producing product Control Engineering Reduce Energy Consumption: Power supply distribution in cement plants Many young engineers consider cement plants pretty complicated because of their weird technology The reason probably lies in the fact that you cannot understand all those technologies unless you worked in such a plant and saw all processes from scratchThe essentials of electrical systems in cement plants EEP

Cement ABB

Electrical powertrain for heavy working machines, without subtitles (English mp4 Movie) Driving value Sophisticated ringgeared mill drives from ABB ABB Review article (English pdf Article) Success in Vietnam Total plant solution for the Cam Pha cement plant (English pdf Article) created by plant optimization and information technology ABB’s systems capabilities are essential tools for minimizing energy consumption and improve quality Drives Applications ABB manufactures motors and drive systems worldwide, from the subkilowatt to the megawatt ratings of the gearless drives for the largest SAG and ball mill applicaCement Plant Solutions for the Cement Industry Holnam Cement in Devilslide, Utah built a new state of the art cement plant in an area with an existing plant This more than doubled the electrical load on the power system served by a relatively weak 46 kV lines by Pacific Corp Across the line starting of 2000 HP ball mill motors in the existing mill was already causing voltage problems to other customers on the power system and tripping a Voltage regulation system during large motor starting and

China Cement Ball Mill, Cement Ball Mill Manufacturers

China Cement Ball Mill manufacturers Select 2021 high quality Cement Ball Mill products in best price from certified Chinese Ceramic, Ceramic Product suppliers, wholesalers and factory on Madein Benue Cement Plant The closed circuit grinding plant is shown in Figure 1 The cement mill tube is a twochamber mill with a length of 15m and diameter of 44m and rotates at aTribological Processes in a Ball Mill for Ordinary The selection of AC induction motors for cement mill applications, with reference to fan, kiln and vertical mill applications Cement plant applications present an immense matrix of application criteria to specify, design and build motors properly Operating conditions Basic motor specifications begin with determining the motor nameplate horsepower (hp) and revolutions per minute (rpm) TheseSelection of AC induction motors for cement plant

A decision support tool for cement industry to select

1 Introduction The cement market plays a central role in economic growth of developing nations This contribution can be demonstrated by the added value of the cement production to the national domestic production and job opportunities []Demand for cement in construction drives production and without hindrance on the demand side, the cement production is expected to grow Cement manufacturing is a highly energyintensive process where the main energy sources used are coal (or alternatively coke) and electricity (Bhattacharya and Saha, 2015; Madlool et al, 2011)Typically, coal and coke makes up the vast majority of energy consumption on a cement plant (Pelser, 2017)However, it is important to note from Fig 1 that the cost component of electricity far Results and prospects of applying an ISO 50001 based A Chinabased cement plant used VFDs to significantly reduce its energy consumption in its dryprocess kilns, responsible for production of 14 million tons of cement each year Traditional damper control systems used a fixed amount of energy, so fans at the plant always ran at full capacity even when the facility wasn’t producing product Control Engineering Reduce Energy Consumption: Cement