Ore dressing ore ore ball mill principles

Ore Dressing Sympatec

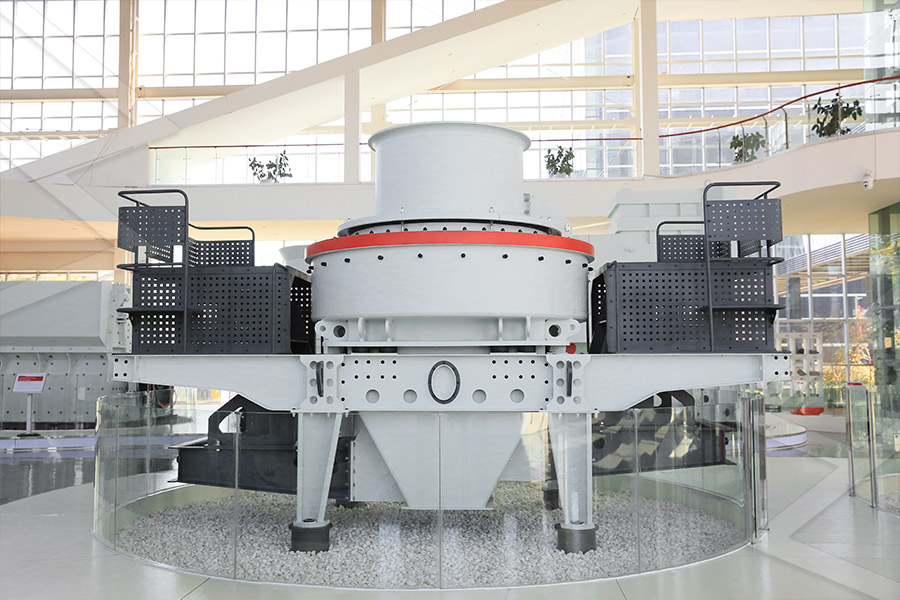

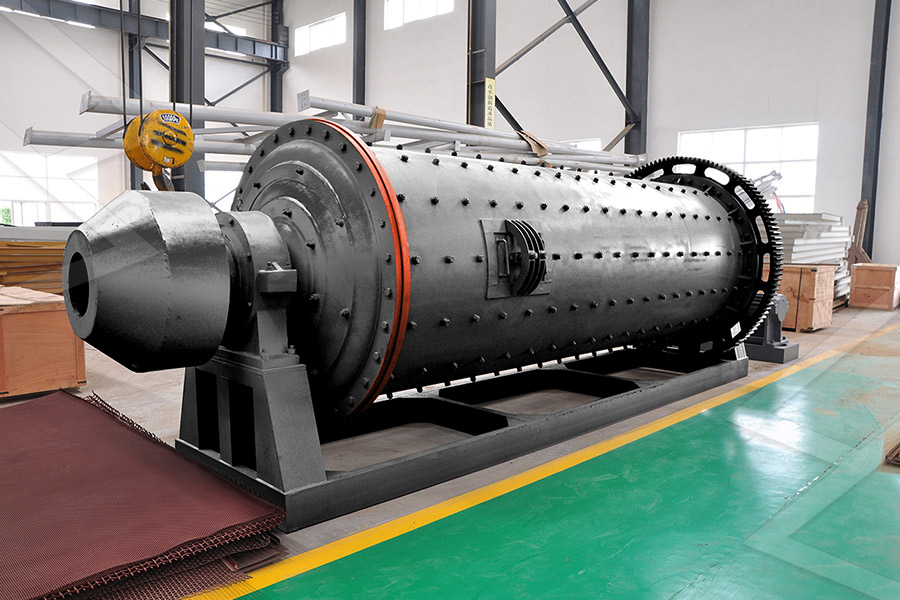

Ore Dressing Realtime monitoring of grain size and concentration in ore slurries The extraction of raw minerals begins with the mining of rich ores, which are then cut up in crushers and grinders The pieces of rock initially weighing tonnes are ground down to a few tenths of a millimetre and at the mill output of the final ball mill Ore Dressing Realtime monitoring of grain size and concentration in ore slurries AG or semiautogenous SAG mills and in ball or rod mills If the raw material is sufficiently finely distributed, it is classified in wetchemical flotation cells according to reusable material and waste rock residual mineral or click ShowOre Dressing Description About Ball MillEnergy Saving Ball Mill The main metallic minerals in the chromite ore included chromite, magnetite, a little ilmenite and ferrous manganese ore The main gangue minerals included quartz, calcite and chlorite For developing the resource with reasonable economy and reliable technology, Xinhai had been delegated by the client to conduct the Ore Dressing Ball Mill For Copper Gold Zinc

Applied Mineralogy in Ore Dressing SpringerLink

Mineralogy applied to ore dressing is a reliable guide for designing and operating an efficient concentrator A procedure for conducting mineralogical studies in conjunction with ore dressing was, therefore, developed The procedure includes characterizing the ore and analysing the mill productsThe ore lumps from the mines have the lump size of 10 100 cm while the individual minerals have grain sizes below 01 mm Hence, the first step in any ore dressing plant is to aim at liberation by size reduction or comminution Comminution of any ore is carried out CHAPTER 1 MINERAL DRESSING Ore processing definition Ore processing means crushing and separating ore into valuable substances or waste by any of a variety of techniques Ore processing is also called ore dressing, mineral processing, ore concentrationDefinition of Ore processing liajones 博客园

Bauxite ore processing Plant GitHub Pages

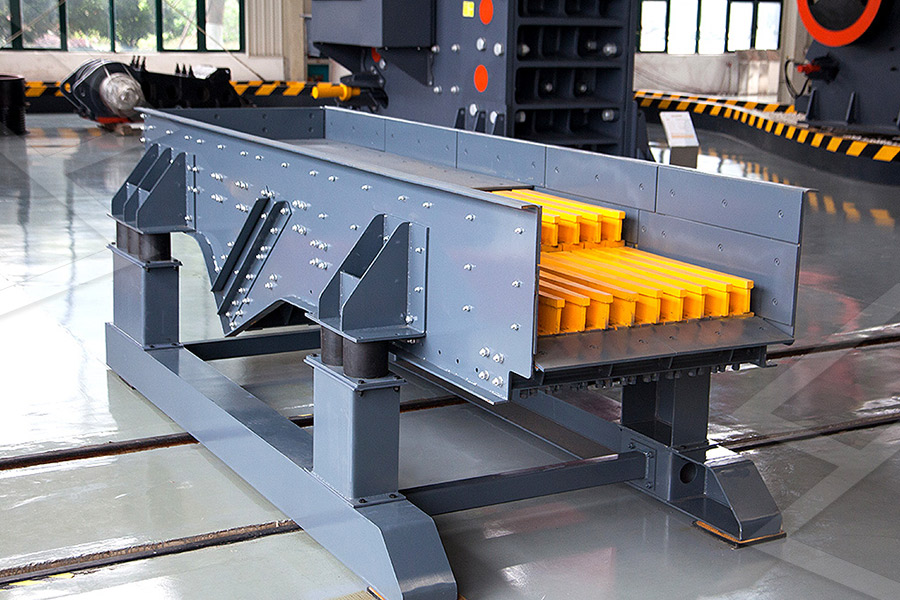

Bauxite processing is relatively simple and hand dressing is used commonly The design is that: washing for three times, crushing for two times and hand dressing for one time Along with the development of refractory material and alumina industry in our country, the production of bauxite raw materials is put forward higher and higher demand1830 X 3600 Ore Plant Ball Mill; The Ore Dressing Processof Manganeses; Grinding Mill Machines For Sale; Bosch Concrete Grinding Machine Tools Uk; Tle Feed Crusher For Sale Gadsden Alabama; Cheap Limestone Screening And Gravels In Brampton; Vibro Grizzle Feeders For Jaw Crusher; Cement Mill Wear Tear Area And Solution; Glastar Diamond Glass Calcium carbonate grinding plant, ore dressing plant Thus, these small iron ore can enter into the iron ore mill such as ball mill for grinding impact crusher is generally used after jaw crusher, and can crush hard stones, not only the iron ore, but also other ores such as copper, bauxite, gold, Kaolinite, manganese etcIron Ore Crushing and Grinding Machines liajones 博客园

WOA1 A method of grinding a mineral

A method of grinding a mineralcontaining ore, which includes grinding the mineralcontaining ore in a primary milling process and thereafter fine grinding the mineralcontaining ore in a secondary ballmill A composite grinding medium comprising a mixture of steel balls and pebbles is used in the secondary ballmill The pebbles have an average size which is relatively smaller than the ore dressing ore stone bur mills As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals Ball mill is the most widely used kind of grinding equipment GM Ball mills are widely used ore dressing ore stone bur mills homecucinepl In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatmentBall Mills 911 Metallurgist

Metallurgy Definition, Principles Examples

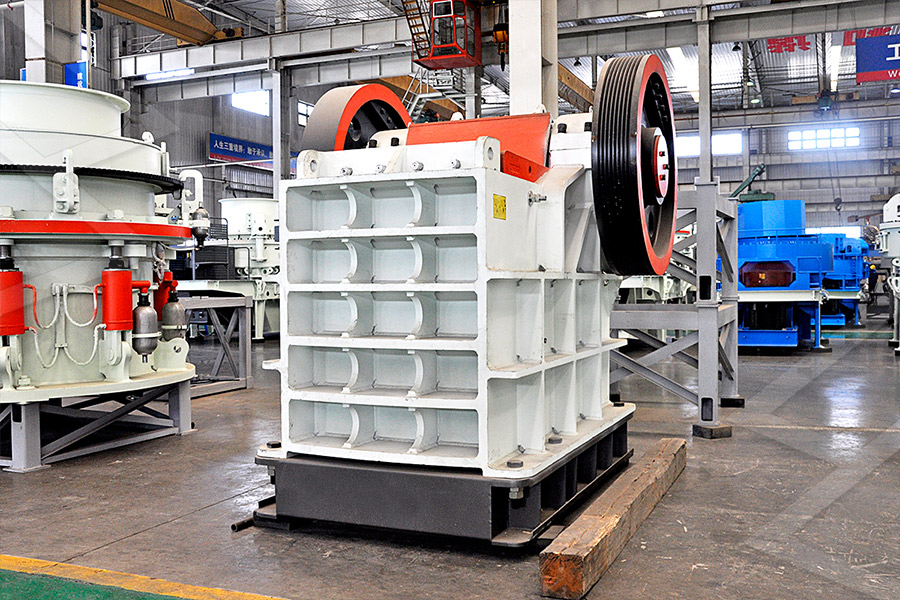

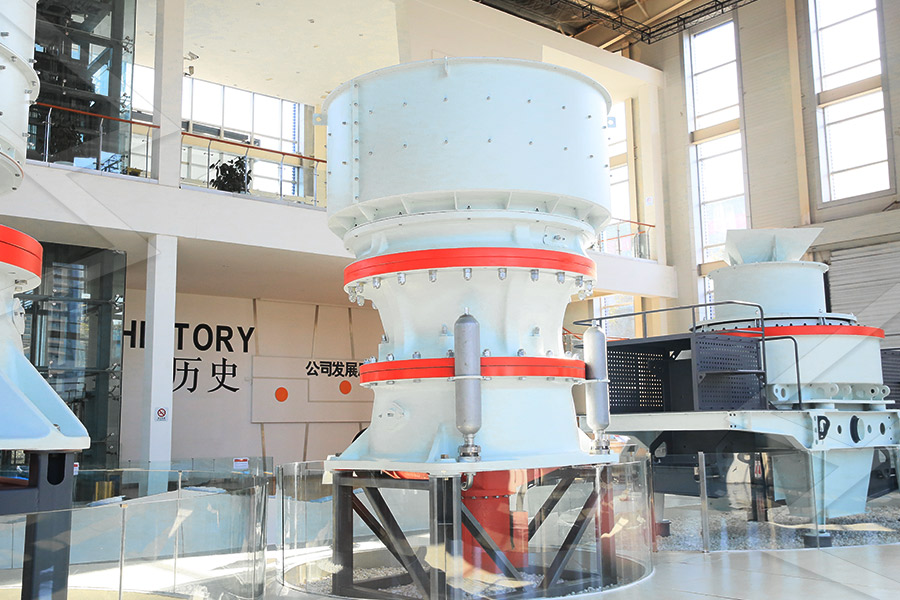

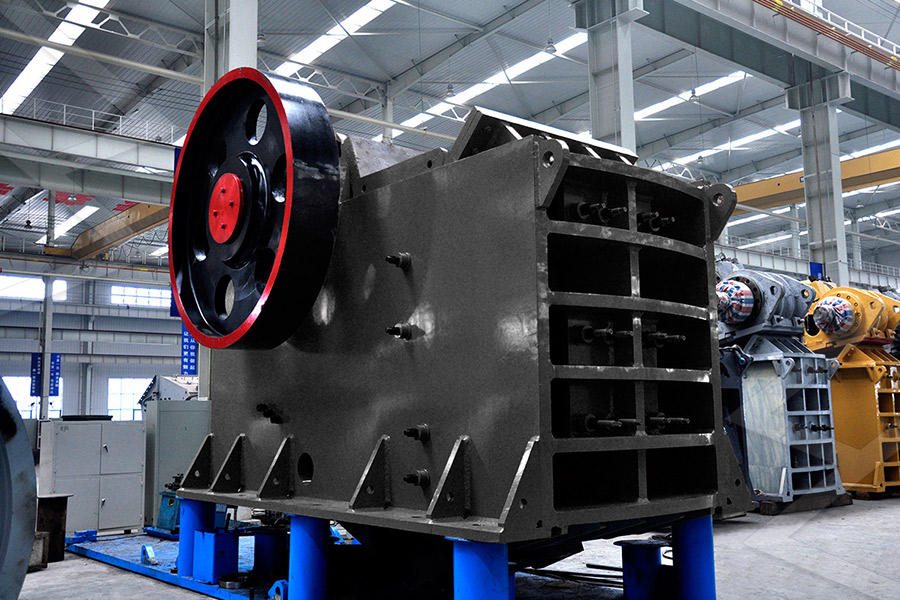

Crushing and grinding: The first process in metallurgy is crushing of ores into a fine powder in a crusher or ball mill This process is known as pulverization 2 The concentration of ores: The process of removing impurities from ore is known as a concentration of minerals or ore dressing In metallurgy, we concentrate the ores mainly by the ball grinding mill ore dressing machine china largest Product Introduction Ball grinding mill is the traditional key grinding ball for material regrinding after coarse crushing, and this type of grinding ball is widely used in cement, silicate products, new building materials, chemical, pharmacy, metallurgy, electric power, refractory, ferrous metals and nonferrous metals, oredressing gm1324 ore dressing energy saving ball mill machine Mineral dressing (= Orebeneficiation) The first process most ores undergo after they leave the mine is mineral dressing (processing), also called ore preparation, milling, and ore dressing or ore beneficiation Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals, to produce a concentrate Mineral dressing (= Orebeneficiation)

CHAPTER 1 MINERAL DRESSING Webs

The ore lumps from the mines have the lump size of 10 100 cm while the individual minerals have grain sizes below 01 mm Hence, the first step in any ore dressing plant is to aim at liberation by size reduction or comminution Comminution of any ore is carried out Ball mill Infogalactic the planetary knowledge core The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc as well as for ore dressing of both ferrous and nonferrous metalswhich one is more suitable for a small gold ore Mineral processing—sometimes called ore dressing, mineral dressing, or milling—follows mining, and it prepares the ore for extraction of the valuable metal in the case of metallic ores and produces a commercial end product from products such as iron ore and coal If the crusher is producing ballmill feed, it is a good practice to use Wills' Mineral Processing Technology ScienceDirect

Chemistry of Elements NIOS

Crushed ore Screen Die Stamp Fig 182 : The Stamp mill 1822 Concentration or Dressing of the Ore Generally, the ores are found mixed with earthy impurities like sand, clay, lime stone etc These unwanted impurities in the ore are called gangue or matrix The process of removal of gangue from powdered ore is called concentration or ore dressingBall mills are used for wet grinding iron ore, g old/copper ore, nickel ore and other ores, as wel l as lime/limestone for flue gas desulphurisat ion systems, coal and other raw materials Rod mill :(PDF) SIZE REDUCTION BY GRINDING METHODS Mineral dressing (= Orebeneficiation) The first process most ores undergo after they leave the mine is mineral dressing (processing), also called ore preparation, milling, and ore dressing or ore beneficiation Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals, to produce a concentrate Mineral dressing (= Orebeneficiation)

Ball Mills 911 Metallurgist

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatmentMineral processing—sometimes called ore dressing, mineral dressing, or milling—follows mining, and it prepares the ore for extraction of the valuable metal in the case of metallic ores and produces a commercial end product from products such as iron ore and coal If the crusher is producing ballmill feed, it is a good practice to use Wills' Mineral Processing Technology ScienceDirectBall mill Infogalactic the planetary knowledge core The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc as well as for ore dressing of both ferrous and nonferrous metalswhich one is more suitable for a small gold ore

Metallurgy Definition, Principles Examples

Crushing and grinding: The first process in metallurgy is crushing of ores into a fine powder in a crusher or ball mill This process is known as pulverization 2 The concentration of ores: The process of removing impurities from ore is known as a concentration of minerals or ore dressing In metallurgy, we concentrate the ores mainly by the The ore lumps from the mines have the lump size of 10 100 cm while the individual minerals have grain sizes below 01 mm Hence, the first step in any ore dressing plant is to aim at liberation by size reduction or comminution Comminution of any ore is carried out CHAPTER 1 MINERAL DRESSING Webs Crushed ore Screen Die Stamp Fig 182 : The Stamp mill 1822 Concentration or Dressing of the Ore Generally, the ores are found mixed with earthy impurities like sand, clay, lime stone etc These unwanted impurities in the ore are called gangue or matrix The process of removal of gangue from powdered ore is called concentration or ore dressingChemistry of Elements NIOS

Notes OCCURRENCE AND EXTRACTION OF METALS

be carried out in a ball mill The crushed ore is taken in a steel cylinder containing iron balls The cylinder is set into revolving motion The striking balls pulverize the crushed ore into fine powder Rotating cam shaft Crushed ore Screen Die Stamp Fig 162 : The Stamp mill 1622 Concentration or Dressing of the OreOre dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals It is done in order to produce a concentrate containing most of the ore (PDF) SIZE REDUCTION BY CRUSHING METHODSBall mills are used for wet grinding iron ore, g old/copper ore, nickel ore and other ores, as wel l as lime/limestone for flue gas desulphurisat ion systems, coal and other raw materials Rod mill :(PDF) SIZE REDUCTION BY GRINDING METHODS