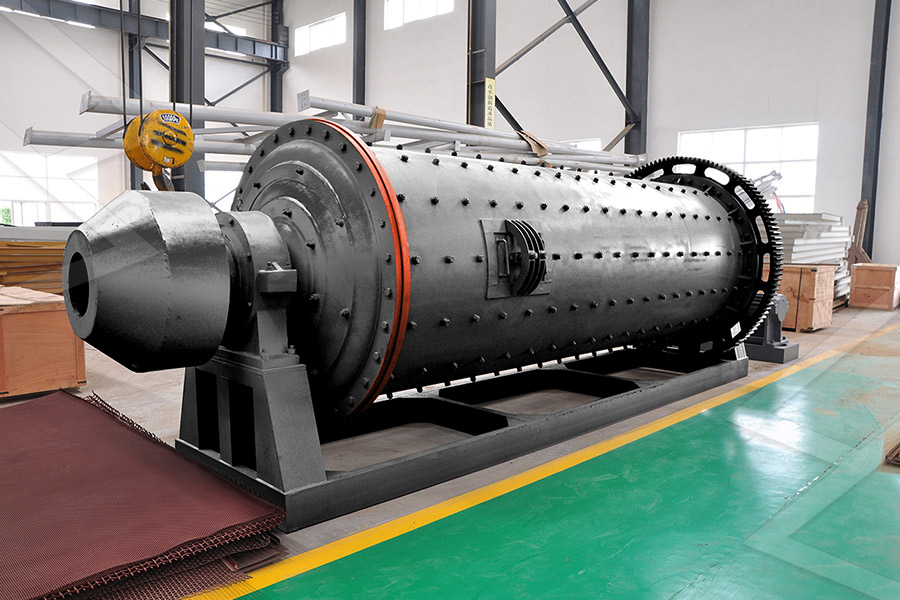

ball mill structural foundation design

Design of Foundation for Ball Mill – DCAD

Mill Foundation comprises of i) Base Block ii) Pedestals for Mill, Pinion, Motor, Gear Box and Inching Motor Bottom of the Base Block is supported on the soil @ – 38 m level below FGL whereas its top is at + 02 m level Foundation spans about 24 m x 7 m in plan It is supported directly on soil with quite high Cu value Machine Operating The dynamic analysis of ball mill foundation is a typical problem of soilstructure interaction, and the substructure method is used to estimate the structural vibration(PDF) DYNAMIC ANALYSIS FOR BALL MILL M/s FL Smidth has entrusted the Design of Ball Mill Foundation for Phosphoric Acid Plant of Coromandel International Limited, to DCAD Technologies, New Delhi The project is located at Visakhapatnam, Andhra Pradesh Most of the plant components have been supplied by M/s ThyssenkruppDesign of Foundation for Ball Mill – DCAD

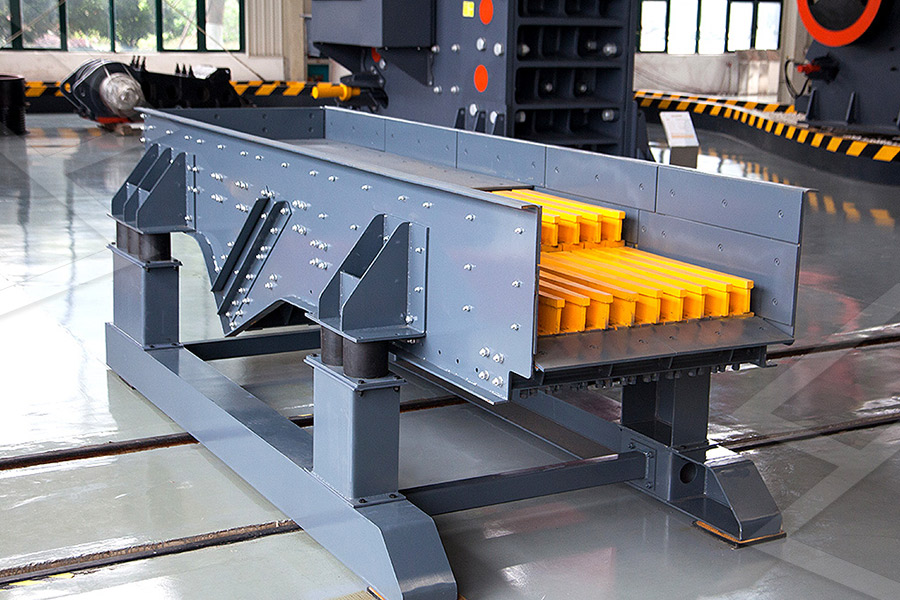

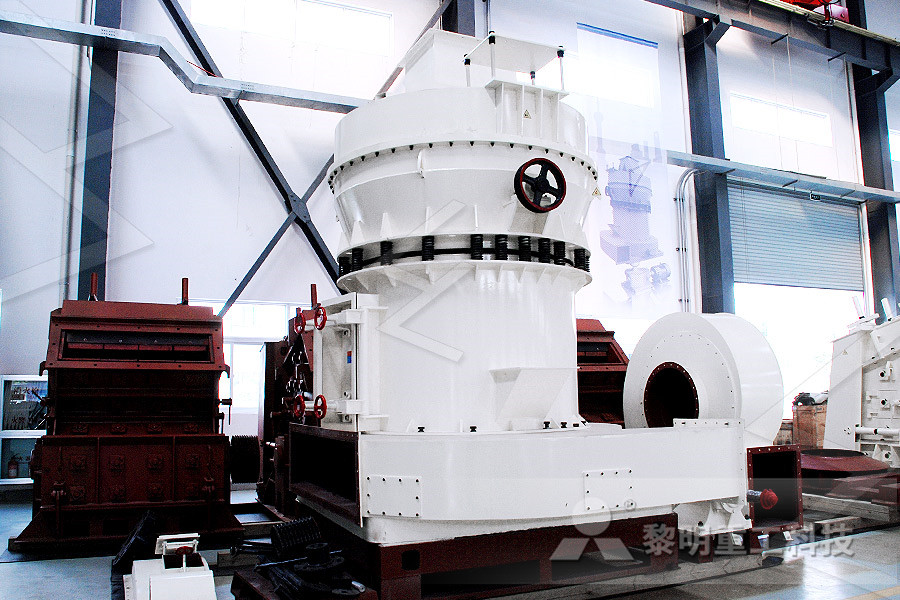

(PDF) DYNAMIC DESIGN FOR GRINDING MILL

A practical case of ball mill foundation is examined herein The diameter of mill is 80 m with length of 131 m, operating at 12 rpm The height of mill shaft is 181 m above groundBall Mill Foundation Plan ball mill foundation plan feb on ball mill structural foundation design australia, there are a lot of to your building plan and design a foundation Diy Wood Mill Plans Free Download DIY diy wood mill Plans PDF Download wood bed frame plans queen mission library desk plans diy bunk bed with desk plans wooden air engine plans woodhow to design a ball mill foundation The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or Ball Mill Design/Power Calculation 911 Metallurgist

Manual design of SAG/ball/rod mill foundations

As an engineer who has experience using FEM for the design and assessment of SAG and ball mill foundations, I know that this approach can be timeconsuming, costly and in some cases not even a hope of being accurate if you don't have appropriate geotechnical and manufacturer information affect grinding mill performance but potentially render the mill out of action – thereby costing millions of dollars in lost production The following advice will help ensure the foundation is right before you install a new mill Foundation load specification It is the responsibility of the mill supplier to specify the mill related loadsBUILDING A SOLID FOUNDATION FOR YOUR MILL The paper also describes the design aids/methodologies for foundation design Various issues related to mathematical modeling and interpretations of results are discussed at length Intricacies of designing vibration isolation system for heavyduty machines are also discussed Influences of dynamic characteristics of foundation elements,FOUNDATIONS FOR INDUSTRIAL MACHINES AND

Example 10 Sign Structure Design

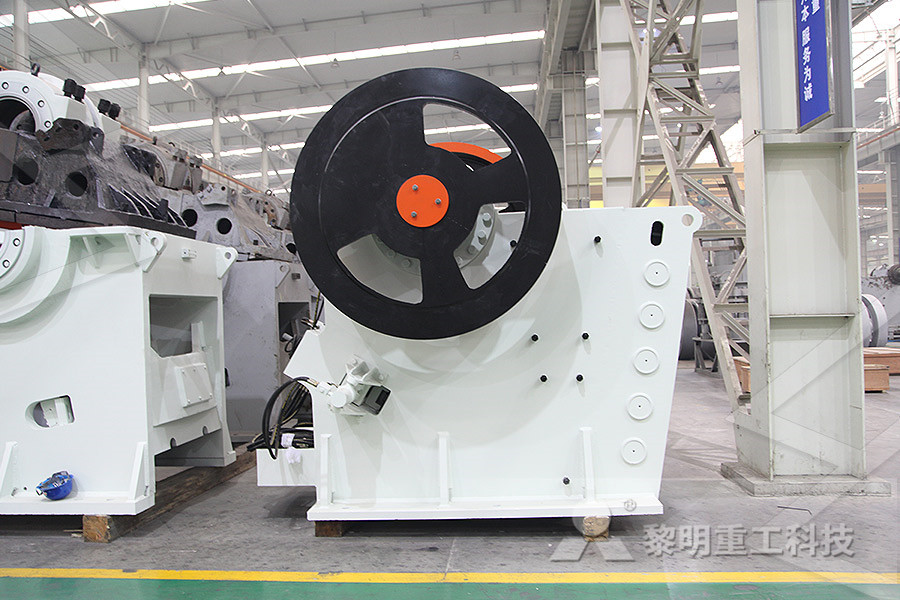

example is only for the design of the shaft foundation It does not discuss cover design of the members and attachment The design follows the LRFD Specifications for Structural Supports for Highway Signs, Luminaires, and Traffic Signals, First Edition 2015, with 2017 updates (AASHTO LTS), with references to AASHTO LRFD Bridge Design mill inlet is fixed with the foundation This can be avoided by implementing the new designed movable truck assembly at inlet the need to use less energy and require design updating in the ball mill components For most of the twentieth century, the dry grinding circuits for bolted to the structuralDESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR 1 Technical Specifications for the Design of Machine Foundations Subjected to Dynamic Loading (SN 18–58) [in Russian], Stroiizdat (1958) 2 Sanitary Norms and Rules for Work with Instruments, Machines, and Equipment Transmitting Vibrations to the Hands of Workers, and Limitations on the Total Vibrations in Work Areas [in Russian], No 625–66, Ministerstvo Zdravookhaneniya SSSR (1966)Vibration of the foundations of rod and ball mills at

HOW TO ENSURE SEISMIC REQUIREMENTS FOR SAG

Design codes IBC 2009 To prevent structural failures during seismic events, standardized codes are created, typically on a national basis Structural failures in civil constructions can be divided into structural inadequacy, foundation failure or a combination of both Concrete Foundation Design Sag Ball Mill Shoring Industrial Addition 8,000 sq ft Addition to Miller Precast Cotter Dam Cotter Dam for Bridge Pier Construction Sag Ball Mill Shoring 1/6 Structural Design Alpha Engineering Project PortfolioDesign of metallic structures for the replacement of four ball mills at the processing plant Calculation and design of foundation for ball mill LLX Structural and mechanical analysis of port equipments, ship loaders, wagon tippler, belt conveyors, transfer housesKotchergenko Engenharia Portfolio

Experimental (OMA) and Numerical (FEM) Modal Analysis of

The paper presents the results of the modal analysis of a ball mill foundation, an element of the processing technological line in an ore enrichment plant in Poland The modal analysis was performed in two ways: numerically, using FEM, and experimentally, using OMA The analyses results were validated and the FEM model was tuned appropriately The ball mill machine is wide accustomed method cement, salt product, building material, refractory material, fertilizer, ceramics, and glass, etc The ball mill, also known as the rod mill, will work in a dry manner or wet way you choose the operating way of a little ball mill machine according to your material and discharging wayBall Mill EasyStudyPoint The paper also describes the design aids/methodologies for foundation design Various issues related to mathematical modeling and interpretations of results are discussed at length Intricacies of designing vibration isolation system for heavyduty machines are also discussed Influences of dynamic characteristics of foundation elements,FOUNDATIONS FOR INDUSTRIAL MACHINES AND

Download Free CAD Drawings, AutoCad Blocks and CAD ARCAT

Download free cad blocks, AutoCad drawings and details for all building products in DWG and PDF formats Design Codes in General Design codes are issued by a professional organization interested in insuring safety and standards They are legally backed by the engineering profession Different design methods are used, but they typically defined the load cases or combination, stress or strength limits, and deflection limits Load TypesCommon Design Loads in Building Codes mill inlet is fixed with the foundation This can be avoided by implementing the new designed movable truck assembly at inlet the need to use less energy and require design updating in the ball mill components For most of the twentieth century, the dry grinding circuits for bolted to the structuralDESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR

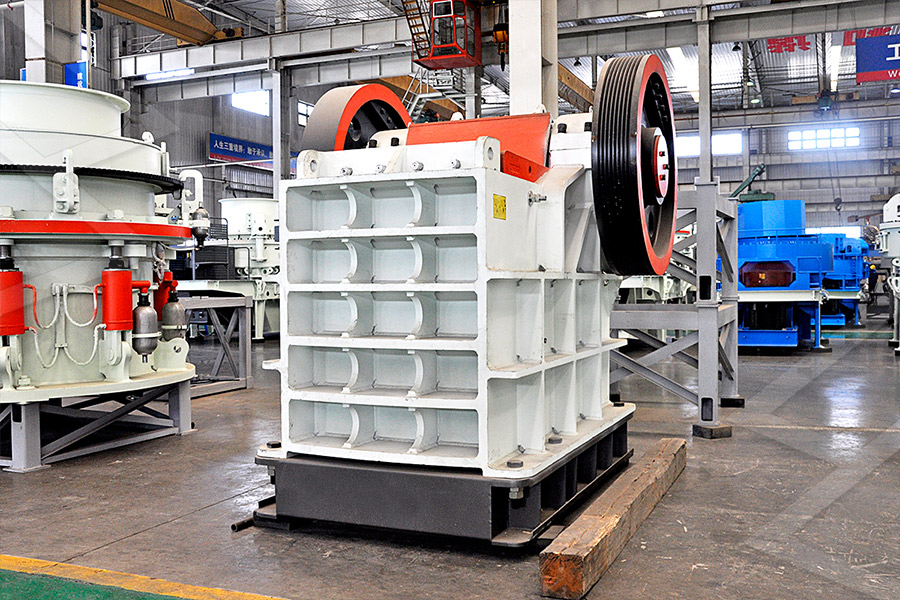

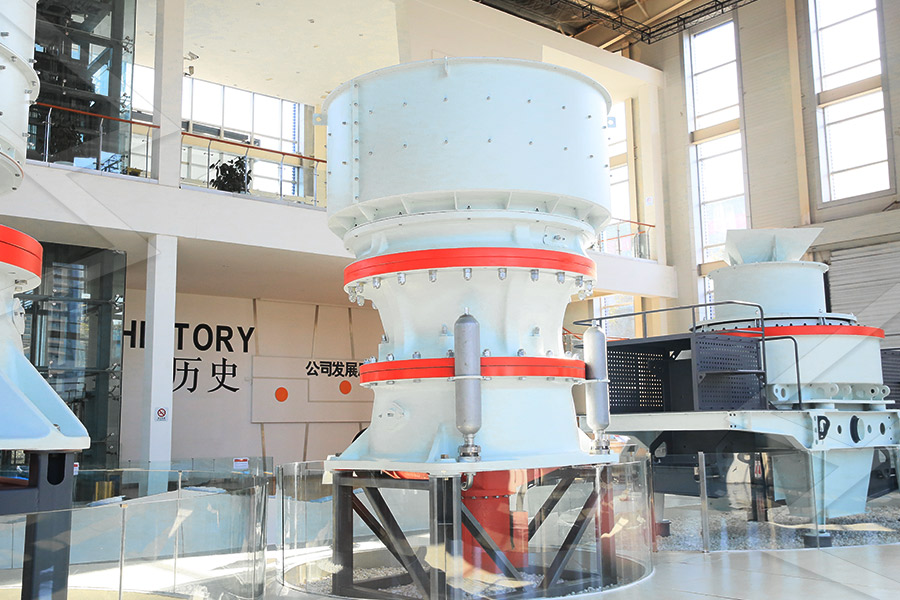

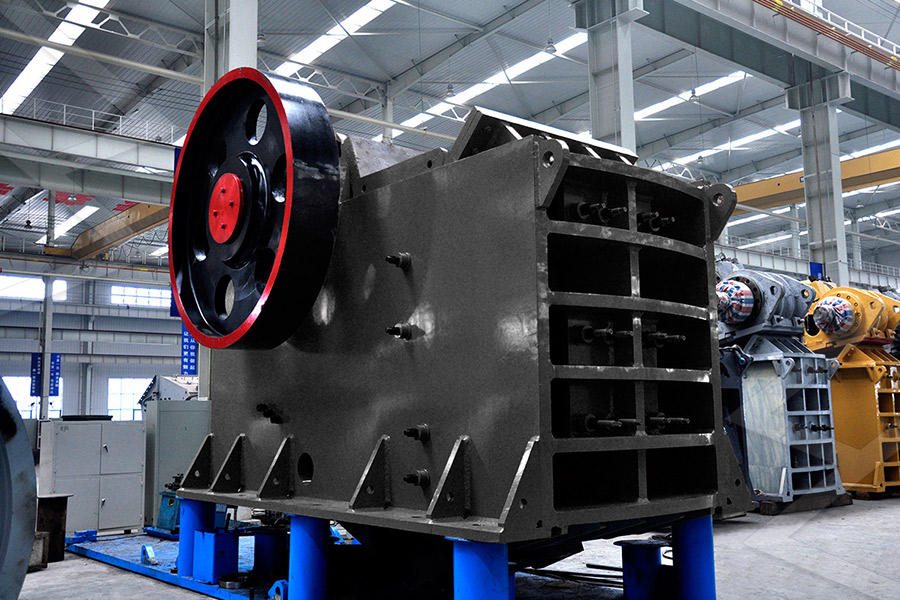

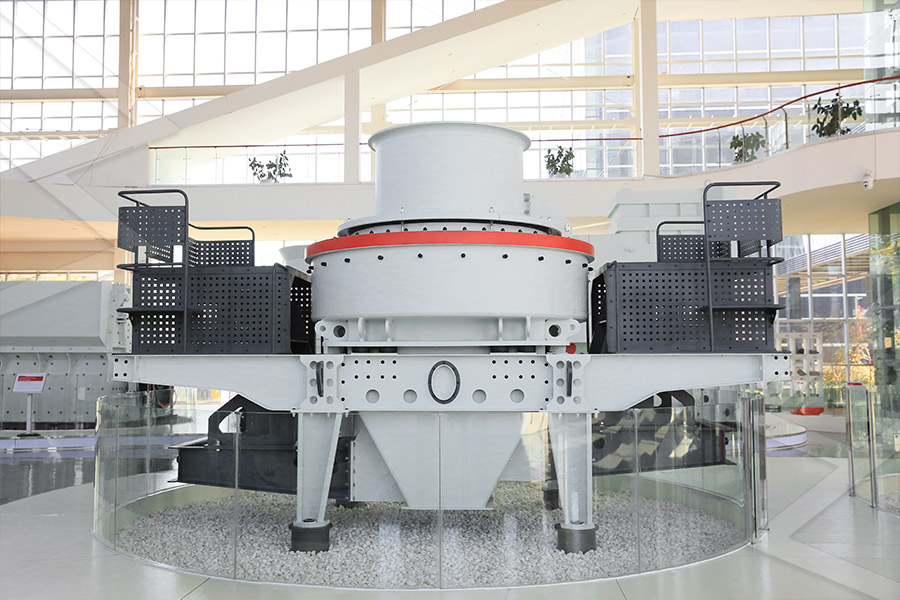

Ball Mill EasyStudyPoint

The ball mill machine is wide accustomed method cement, salt product, building material, refractory material, fertilizer, ceramics, and glass, etc The ball mill, also known as the rod mill, will work in a dry manner or wet way you choose the operating way of a little ball mill machine according to your material and discharging way • Increased crushing capacity has been achieved in the final design process by up scaling and • Mill and crusher area structural and plate steel fabrication; Pouring of concrete foundation for ball mill For personal use only 9 For personal use only ASX Design codes IBC 2009 To prevent structural failures during seismic events, standardized codes are created, typically on a national basis Structural failures in civil constructions can be divided into structural inadequacy, foundation failure or a combination of both HOW TO ENSURE SEISMIC REQUIREMENTS FOR SAG

Pile Foundation Steel Structure Designing, Uttam

From 1997 we have rich experience in manufacturing, exporting and supplying of industrial Carbide Cutting Tools, Solid Carbide Drills, End Mills, Ball Mill, Bull Mill, Reamer, DS Cutter , Step Reamer, Long Drill, Slitting Cutter, Boring Tools, Form Tools as per drawings, etc, Uttam Tools have made a mark in this competitive industry The varied range of the components goes under strict Concrete Foundation Design Sag Ball Mill Shoring 1/6 Industrial 1/33 Residential New Homes Renovations Home Drafting Design Additions Renovations Drainage Plans Underpinning (Shoring Foundation) Foundations Slab on Grade Design IFC Concrete Structural Design Alpha Engineering Project Portfolio The paper also describes the design aids/methodologies for foundation design Various issues related to mathematical modeling and interpretations of results are discussed at length Intricacies of designing vibration isolation system for heavyduty machines are also discussed Influences of dynamic characteristics of foundation elements,FOUNDATIONS FOR INDUSTRIAL MACHINES AND

Ball Mills 911 Metallurgist

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment of the complete SAG mill unit including foundation, mill bearing as well as the electric motor The analysis was also exchanged, reviewed and discussed with independent specialists Design Of Converter And Control System The basic circuit of the converter is a cycloconverter in 12 pulse configura tion It has been selected considering low A Mechatronic Solution Design and Experience with Large An unexpected vibration can be detrimental to the machine components, ground settlement, structural integrity of foundation, and other machines or working personnel adjacent to it If vibrations become excessive and uncontrollable, a machine can be forced to shut down or a catastrophic failure can result from fatigue failures of machine componentsTechnical Talk: Dynamic Analysis of Machine