longwall al mining equipment

Longwall Mining Equipment Barloworld Equipment

longwall mining was limited by the type of coal to be cut With Cat, this is no longer the case Advancements in drive, control and transmission systems – with more powerful motors, stronger plow chains, increased plow speeds, higher advancing force provided by the roof supports, precise control of the cutting depth, and plowLongwall mining is a form of underground coal mining where a long wall of coal is mined in a single slice The longwall panel is typically 3 – 4 km long and 250 – 400 m wide It is a highly productive underground coal mining technique Longwall mining machines Dowty and Longwall Mining Dowty Mining The Cat CM200 Series of continuous miners are the machines of choice to perform a room and pillar operation to develop longwall panels The gate roads provide passages for longwall equipment, workers and conveyor belts used to transport coal to the surface Roof support is one of the main bottlenecks in entry roadway developmentLongwall Mining Equipment Caterpillar Global

Longwall Mining Coal Education

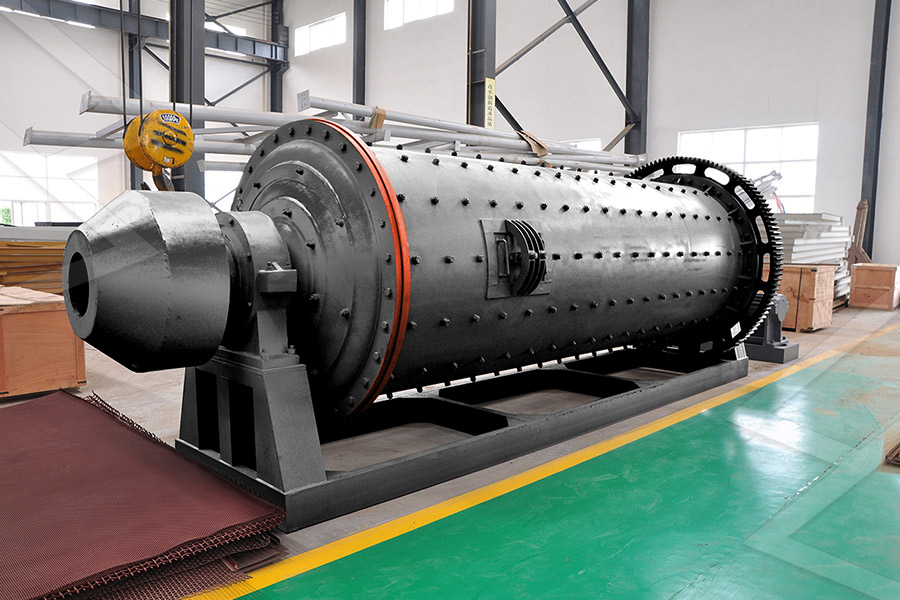

Longwall mining machines consist of multiple coal shearers mounted on a series of selfadvancing hydraulic ceiling supports The entire process is mechanized Longwall mining machines are about 800 feet (240 meters) in width and 5 to 10 feet Underground Longwall Adapted to the mining challenges faced by our customers today, Cat customized systems for longwall mining include hydraulic roof supports, highhorsepower shearers, automated plow systems and armored face conveyors with intelligent drive technology — controlled and supported by advanced longwall automationLongwall Mining Cat CaterpillarLongwall mining is a highly productive underground coal mining technique Longwall mining machines consist of multiple coal shearers mounted on a series of selfadvancing hydraulic ceiling supports The entire process is mechanized Longwall mining machines What is Longwall Mining? (with pictures)

Coal Mining Machinery Longwall,Underground Mining

MES specialize in thin low coal seam longwall mining equipment,coal washing process equipment manufacturer and ore mineral processes with energy saving and lifecycle cost reduction Selected Mining Equipment Manufacturer Contractors Site map +86 28 ; g; Caterpillar is the only manufacturer able to provide a complete modular family of powerful controllers that integrate fully with Cat longwall equipment The Cat PMC® family of Programmable Mining Controls offers onestop shopping for all the controls, sensors and components a successful longwall system needsLongwall Mining Cat Caterpillar The longwall was a China National Coal Mining Equipment (CME) top caving face, 240 metres wide and with a 2km panel length The operation is a 365 days, 24/7 operation The mine, which features two top coal caving faces and which has been operating since January 2005, has planned utilisation to keep the output conveyor belt fullChinese Longwall Manufacturers Coal, Colliery and

Face Supports Equipment Selection Longwall

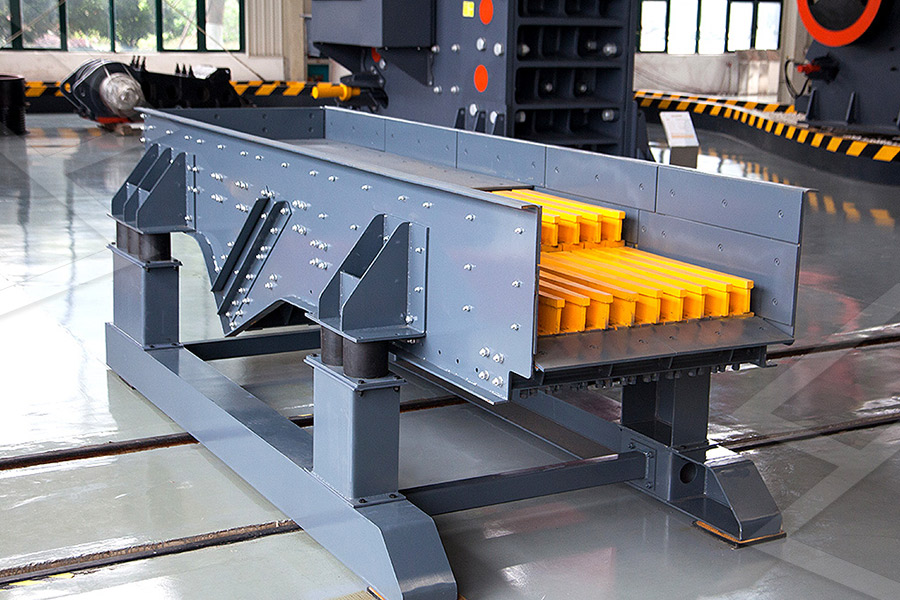

equipment selection b) Face Supports While it is frequently argued (correctly) that all items on a longwall face have to be considered as parts of an integrated unit and be fully compatible, it cannot be denied that poorly designed and inadequate roof supports are likely to have a greater effect on results than other items, and to that extent are more importantIn the field, the performance of Longwall Associates equipment speaks for itself – just ask our customers Longwall specializes in fullycustomized equipment handcrafted in the heart of Eastern US coal country, offering you a full line of longwall conveyors with superior and unrivaled Power, Production and Performance At Longwall Associates we don’t sell equipment “models,” we sell Longwall :: Products HOT complete longwall coal mining units represent the ultimate solution for highproduction low coal seam longwall mining HOT incorporates bestinbreed low coal seam coal shearers, roof supports, armed face conveyors (AFC), bridge stage loaders (BSL), crushers, and belt conveyors to deliver a complete low coal seam longwall coal mining unitunder ground Low Coal Seam Longwall Mining System

Longwall Equipment – The Mining Window

Northcliff, Randburg, Johannesburg, 2195 +27 82 412 8638 stuart@chartechnicalongwall mining Mining a mining method in which very long rectangular blocks of coal are defined during the development stage of the mine and then extracted in a single continuous operation by an automated cutting head moving parallel to the coal faceWhen the coal is cut, the working area is protected by a movable, powered roof support system As the face progresses, the immediate roof above Longwall Mining an overview ScienceDirect Topics US coal mining output is shown graphically from 1900 to 1975, according to (1) total and percent underground, and (2) tonnage by mining method (conventional, continuous, long wall) Innovative mining equipment for the various mining methods is discussed in detail, with emphasis on productivity, safety, and conveyor practiceLongwall/shortwall mine equipment availability and

Longwall Mining Cat Caterpillar

Cat Longwall Automation Automation is an integral part of a modern longwall mining operation, allowing the system to work safely and productively around the clock Ensuring that every piece of equipment is connected and communicating quickly and reliable is critical, and that’s where the Cat® PMC family of Programmable Mining Controls comes in longwall face, with the hydraulic roof supports on the left hand side and the coal face on the right hand side of the picture The drum in the background is the rotating cutting head of the coal shearer and the chain conveyor can be seen in the foreground Fig 13 Typical Longwall Face Equipment Coal Seam Direction of mining Goaf Longwall shearerIntroduction to Longwall Mining and Subsidence ver2 The principle of longwall mining is the use of a large cutting head or shearer which traverses the coal seam breaking it up and depositing the coal onto an armoured conveyor to transport the coal Longwall mining demands safety and reliability in

Longwall coal mine Twentymile Colorado Mining

The coal transport system has been supplied by Continental Conveyor, with a 18mwide main belt conveyor capable of handling 5,000t/h of runofmine coal at a speed of 4m/s This system was upgraded during 2006 with the purchase of a new longwall equipment setHowever, longwall mining has difficulty achieving efficient production in coal seams taller than 6 meters (20 feet) This is primarily due to the fact that shearers, roof supports and other equipment large enough to mine those seams is prohibitively expensive — not only because of the cost to purchase them, but because their tremendous weight Viewpoint Mining Magazine Longwall TopCoal Caving Longwall mining is a highly productive underground coal mining technique Longwall mining machines consist of multiple coal shearers mounted on a series of selfadvancing hydraulic ceiling supports The entire process is mechanized Longwall mining machines are about 800 feet (240 meters) in width and 5 to 10 feet (15 to 3 meters) tallLongwall Mining Coal Education

Longwall Mining Cat Caterpillar

Adapted to the mining challenges faced by our customers today, Cat customized systems for longwall mining include hydraulic roof supports, highhorsepower shearers, automated plow systems and armored face conveyors with intelligent drive technology — controlled and supported by advanced longwall automationLongwall Mining Equipment Product Line Overview Open the catalog to page 1 Roof Supports Customized Design Caterpillar is the world leader in longwall roof support technology In the early 1970s, demanding mining conditions in German coal mines set the stage for extensive RD in roof support technology Steeply inclined coal seams both thick Longwall Mining Equipment Caterpillar Global Northcliff, Randburg, Johannesburg, 2195 +27 82 412 8638 stuart@chartechnicaLongwall Equipment – The Mining Window

Longwall Top Coal Caving (LTCC) Mining Technology

Longwall Top Coal Caving (LTCC) is a special designed longwall mining method for very thick seams (thickness is more than 45m) where good quality coal is being left because "conventional" longwall equipment has not yet been designed to operate successfully beyond around 5m mining height Longwall mining is one of the most efficient methods of coal extraction It is also one of the most demanding Gates combines worldclass material science and expert engineering to manufacture products for the longwall mining industry that can take on the challenges of your longwall mining Longwall Mining GatesPetitto Mine Equipment, Inc offers steel fabrication and machine services with design and manufacturing capabilities Serving the coal industry for more than 50 years, Petitto Mine Equipment, Inc specializes in the manufacture of heavy duty, crawler track mounted longwall move equipmentHome petittomineeq

Longwall coal mine Twentymile Colorado Mining

The coal transport system has been supplied by Continental Conveyor, with a 18mwide main belt conveyor capable of handling 5,000t/h of runofmine coal at a speed of 4m/s This system was upgraded during 2006 with the purchase of a new longwall equipment set The longwall was a China National Coal Mining Equipment (CME) top caving face, 240 metres wide and with a 2km panel length The operation is a 365 days, 24/7 operation The mine, which features two top coal caving faces and which has been operating since January 2005, has planned utilisation to keep the output conveyor belt fullChinese Longwall Manufacturers Coal, Colliery and Longwall mining In the longwall mining method, mine development is carried out in such a manner that large blocks of coal, usually 100 to 300 metres wide and 1,000 to 3,000 metres long, are available for complete extraction (see photograph )Mining Coal Mines