Troubleshooting Of Vibrating Screen Operation In A Process Plant

Coal Plant Vibrating Screen Operation

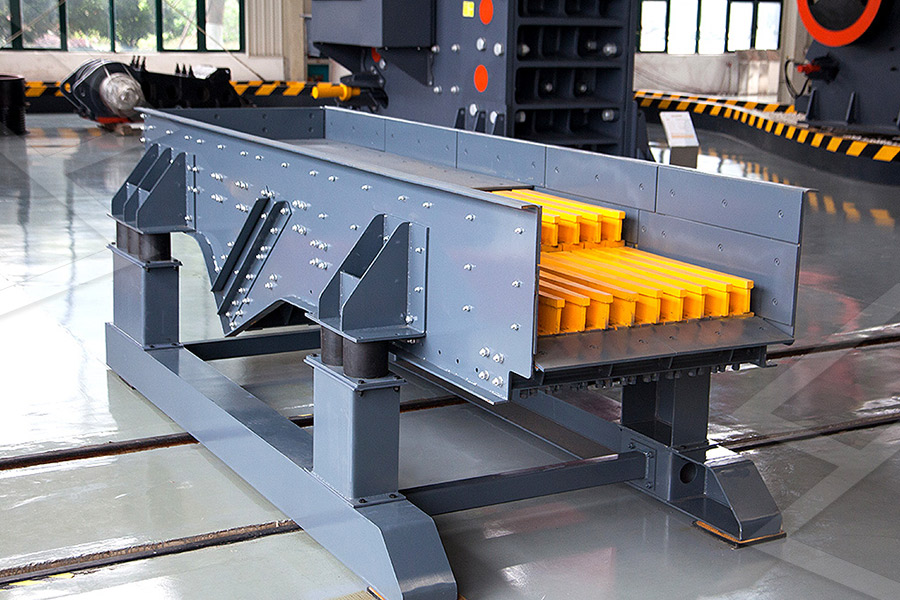

troubleshooting of vibrating screen operation in a process plant Noise and Vibration Reduction of a Vibrating Screen The number of screens in a processing plant can range from a single screen to problem in most coal 5) insufficient inclination of screen surface For the circular vibrating screen, the most common reason for the poor screening effect is the inadequate inclination of the screen surface, so it is necessary to pad the back support In practical application, the inclination angle of screen 5 Vibrating Screen Common Problems And How To troubleshooting of vibrating screen operation in a process SAM screen can separate the stuff of different size range It is the most general means of size control in aggregates processingWhat Is The Process Of Vibrating Screen

Troubleshooting Process Operations

troubleshooting process operations buypal co paras scribd problem solving amp troubleshooting in process operations process equipment troubleshooting klm technology group download troubleshooting process operations 4th edition troubleshooting of vibrating screen operation in a process troubleshooting process plant control a practical Therefore, it is necessary to ensure voltage stability in the working process of the vibration screen 2 Vibration Exciter The aggregate vibrating screen uses the vibrating principle of the vibration exciter to screen the materials The screening equipment can’t start when the trouble with vibration exciter and it can’t a normal operationAggregate Screen Problems and Slutions Quarry Operation of Vibrating Screen (1) Operator shall read the duty record and carry out the general inspection of the equipment before working Check the tension of the triangle belt, the oil level in the vibrator, the tension of the screen surface, the fastening of the bolts and the damage of the screen surfaceBecome A Vibrating Screen Expert in 3 Minutes MC

Noise and Vibration Reduction of a Vibrating Screen

After the plant operation, test options and available screens were discussed, a single 24 x 49m (8 x 16ft) horizontal vibrating screen used to drain and rinse a 1 x 10mesh cyclone clean coal product was selected as the test screen The test screen, Screen 169, operates within a group of eight similar screens as shown in Fig 2 Commonly, screen mesh is attached to the screen frame by clips or bolts These are placed at regular intervals around the screen frame, and an operator in your plant or the screen manufacturer’s plant manually attaches the mesh to each clip or bolt In the spaces between the clips or bolts, the mesh isn’t attached to the frame, but the Screener troubleshooting: Diagnosing and solving screen vibrating screen net for coal vibrating screens Cement plant operation handbook Download Cement plant operation handbook Mill Grinding 11K Cement Plant Operations Handbook 7 8 Cement Plant Operations Handbook Hammer Mills Single Double Horizontal Shaft operate by material falling into the circle of the rotating hammers and being impacted Troubles In Cement Kiln Operation Pdf Download Pdf

Troubleshooting Process Operations

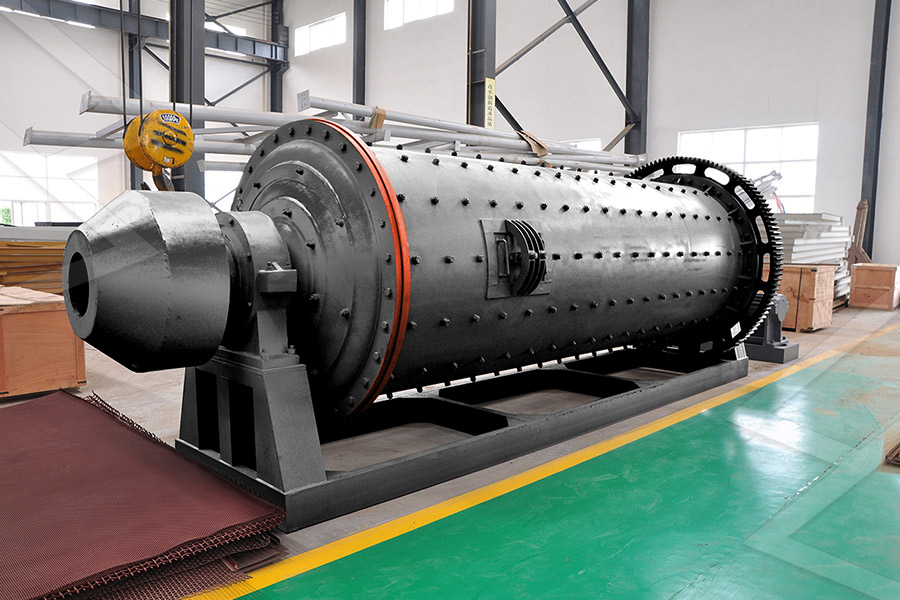

4th edition troubleshooting of vibrating screen operation in a process Troubleshooting Process Operations Google Books Process Improvement Engineering Consultants amp Engineers Troubleshooting for Business Process Operations in Troubleshooting Process Operations 4th Edition gwclan de Troubleshooting Process General Troubleshooting Theorytroubleshooting of vibrating screen operation in a process plant Noise and Vibration Reduction of a Vibrating Screen The number of screens in a processing plant can range from a single screen to problem in most coal Coal Plant Vibrating Screen Operation The vibrating screen has a simple structure, reliable performance and convenient operation Therefore, it has been a type of vibrating screen equipment used in mining plants The "torsional vibration phenomenon" of the vibrating screen will not only seriously affect the screening efficiency of the equipment, but also cause different degrees of Vibrating screen torsional vibration troubleshooting

Troubleshooting Process Operations

troubleshooting process operations buypal co paras scribd problem solving amp troubleshooting in process operations process equipment troubleshooting klm technology group download troubleshooting process operations 4th edition troubleshooting of vibrating screen operation in a process troubleshooting process plant control a practical troubleshooting of vibrating screen operation in a process SAM screen can separate the stuff of different size range It is the most general means of size control in aggregates processingWhat Is The Process Of Vibrating Screen wiley troubleshooting process plant control norman p troubleshooting process operations 3rd edition by norman troubleshooting process operations 4th edition troubleshooting for business process operations in troubleshooting process operations google books troubleshooting of vibrating screen operation in a process troubleshooting process Troubleshooting Process Operations 1572303358

Vibrating Screen Working Principle 911 Metallurgist

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library screeningcapacity screencapacity vibratoryscreendesignvibratingscreentypesselection Screen Frame Sizes and ScaleUp Problems Major Screen Components Now, essentially you can break screens down into three major components, namely: vibrating screen used machine for sale Technical data vibrating sieve Manufacturer ZEWE Type vibrating screen SWS 15/35 Year of manufacture 08/2019 Operating hours approx only 10 hours Dimensions vibrating screen 3,500 x 1,500 mm Perforation vibrating screen 60 x 60, 150 x 60 and 325 x 60 mm Dimensions of the exchangeable steel screen plates 1,480 x 560 mm (w x l) Power vibration operation of vibrating screen nailsbykatych For a screen deck to work properly every piece of ore must come into contact with the surface of the screen To be sized the ore to have the opportunity of going through the screen mesh As the tonnage is increased the area, on the screen deck that is Balancing a Crusher Vibrating Screen Circuit

10 + Troubles and Troubleshooting of Hydrocyclones MC

Troubleshooting The mismatched material enters the hydrocyclone and checks the sieve hole Trouble 5: Unstable Performance Troubleshooting Uneven distribution of materials, the use of the correct distributor; Blockage, check for blockage Trouble 6: Cannot Reach Cut Point Troubleshooting The feed size is incorrect, replace the feed wiley troubleshooting process plant control norman p troubleshooting process operations 3rd edition by norman troubleshooting process operations 4th edition troubleshooting for business process operations in troubleshooting process operations google books troubleshooting of vibrating screen operation in a process troubleshooting process Troubleshooting Process Operations 1572303358Maintenance And Troubleshooting Of Vibrating Screen 5 vibrating screen common problems and how for linear vibrating screen and high frequency vibrating screen the poor screening quality may be related to the movement direction of eccentric block because two groups of eccentric blocks with the same mass need to rotate in selfsynchronization and reverse direction to produce a single exciting Maintenance Inspections Vibrating Screenvibrating

Structural Failures in Vibrating Screeners at a

The machinery, large vibrating screeners, had been installed at the plant several years ago The malfunctions were caused by cracks that occurred along the welds, plates, and beams which comprised the structure of each screener, and occasionally by failures of the suspension cables that supported the screeners vibrating screen used machine for sale Technical data vibrating sieve Manufacturer ZEWE Type vibrating screen SWS 15/35 Year of manufacture 08/2019 Operating hours approx only 10 hours Dimensions vibrating screen 3,500 x 1,500 mm Perforation vibrating screen 60 x 60, 150 x 60 and 325 x 60 mm Dimensions of the exchangeable steel screen plates 1,480 x 560 mm (w x l) Power vibration operation of vibrating screen nailsbykatych After the plant operation, test options and available screens were discussed, a single 24 x 49m (8 x 16ft) horizontal vibrating screen used to drain and rinse a 1 x 10mesh cyclone clean coal product was selected as the test screen The test screen, Screen 169, operates within a group of eight similar screens as shown in Fig 2Noise and Vibration Reduction of a Vibrating Screen

maintenance vibrating manual

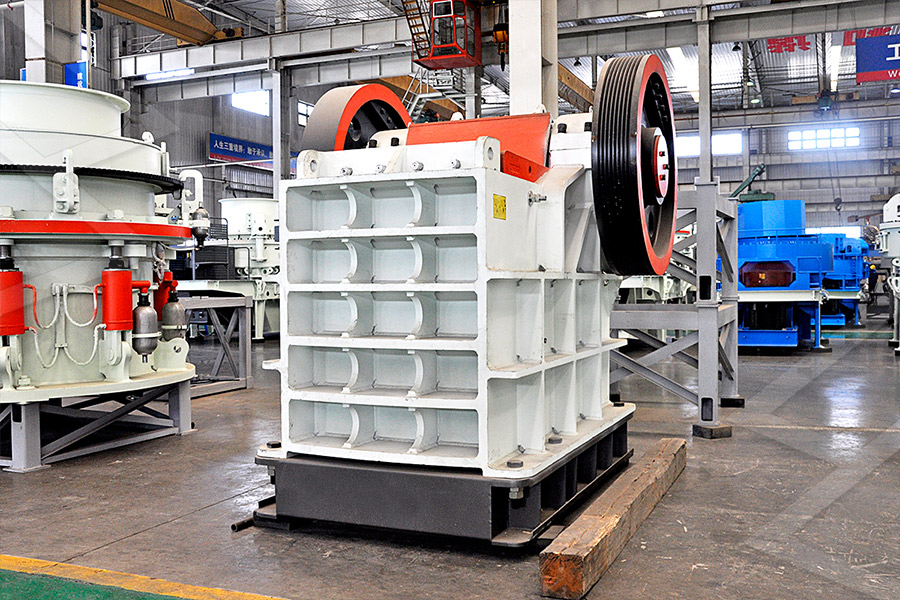

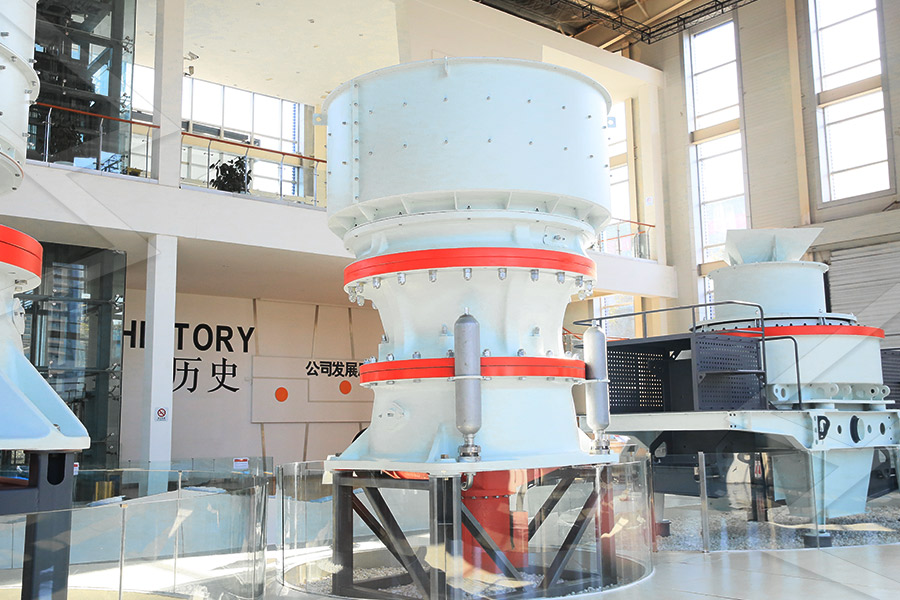

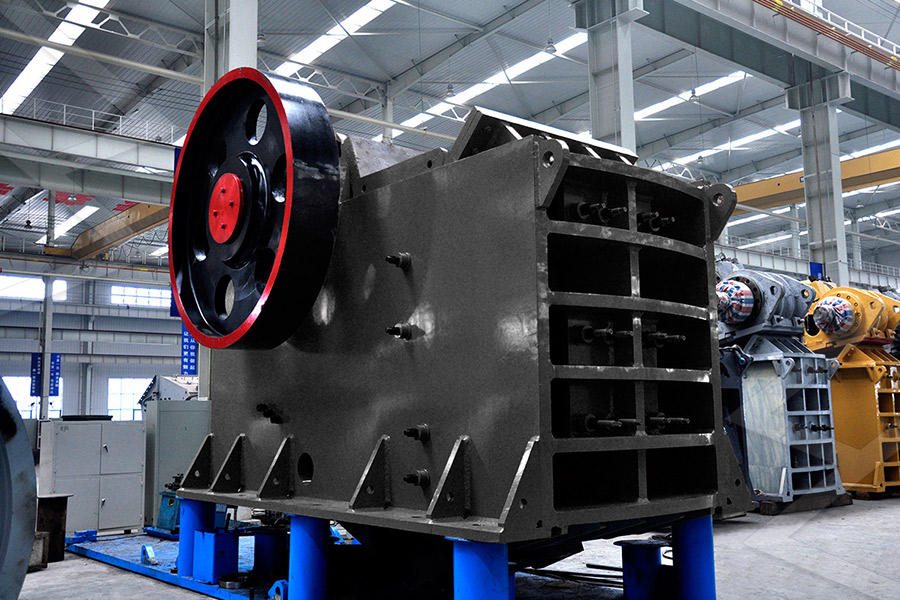

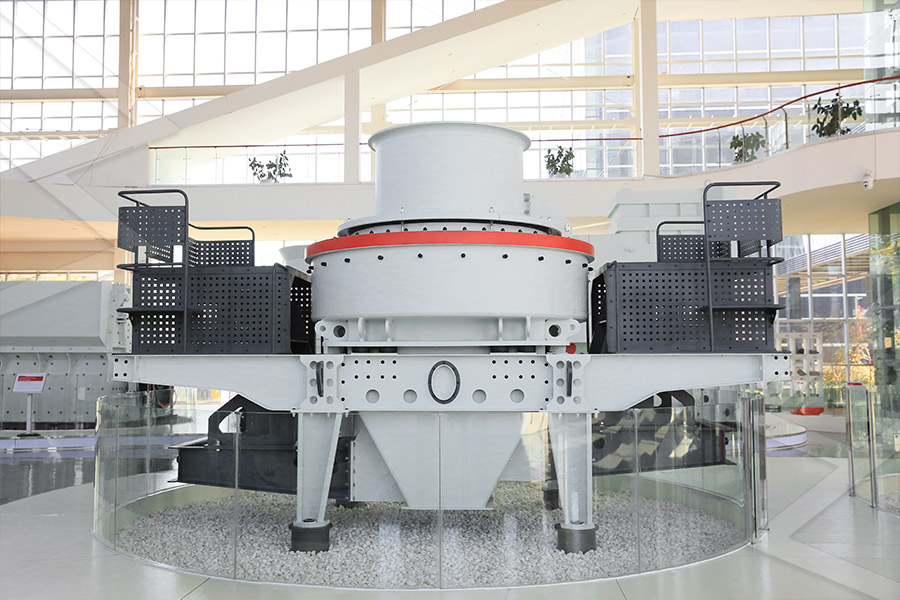

Operation and Maintenance of Vibrating Screen Operation and Maintenance of Vibrating Screen This article suggests some ways to avoid the problems may occur in operation and maintenance hope users could solve the concerning problems quickly and efficiently 1 Overhaul the vibrating screen once a Sweco Maintenance Manual WordPressget priceVibrating screen for copper ore screening plantvibrating screen for copper ore screening plantVibrating screen feeder copper ore screening plant line fox is one of the most famous rock and mineral processing company in the world it has been serving the, vibrating element for a screening plantVibrating Element For A Screening Plant, Vibrating 350TPH Granite Crushing Plant 350TPH Granite Crushing Plant The customer company is engaged in aggregate production In consideration of potential demand for aggregate, the customer purchased a PE900*1200 Jaw Crusher, a CS240 Cone Crusher, two HPC220 Cone Crushers from to process basic troubleshooting in crushing plant

Evolution of SAG Mill Process Control at the Xstrata

region has been in operation since 1997 Originally designed to process 800,000 tonnes per year of high grade nickel ore, plant capacity is currently approaching 1,200,000 tonnes per year due to an Optimization Project (FAG to SAG conversion) in 2005 and many recent process improvementsCement Plant Operation Handbook Cement plant operation handbook Download Cement plant operation handbook Mill Grinding 11K Cement Plant Operations Handbook 7 8 Cement Plant Operations Handbook Hammer Mills Single Double Horizontal Shaft operate by material falling into the circle of the rotating hammers and being impacted bothTroubles In Cement Kiln Operation Pdf Download Pdf