reduction ratio crushing no of Crushers

reduction ratio crushing no of crushers Bussa

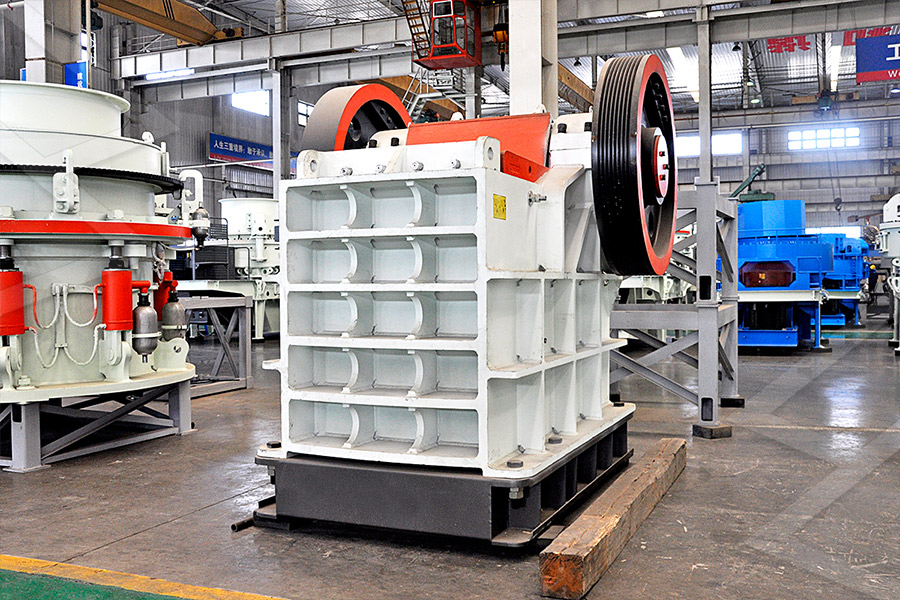

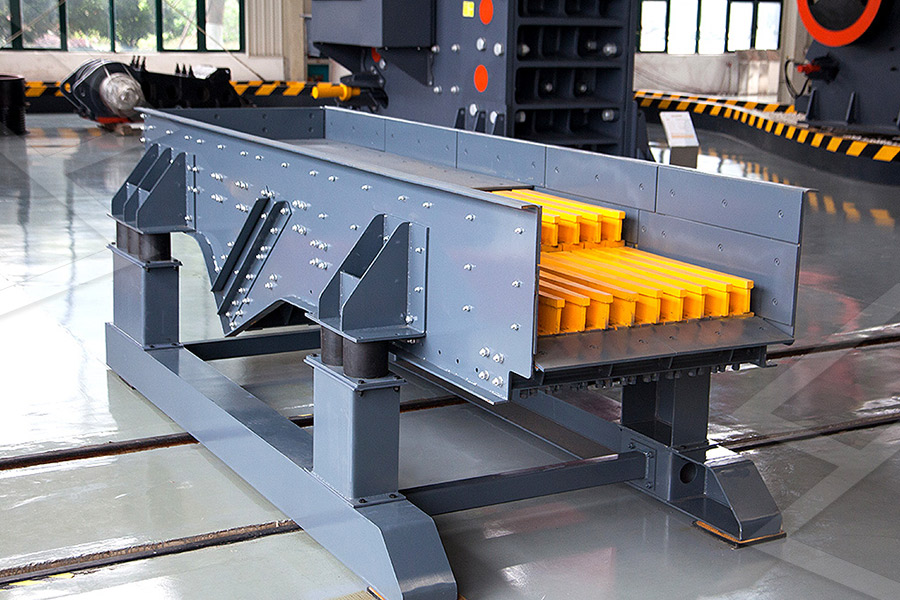

reduction ratio crushing no of crushers R: Size reduction ratio The ratio of the gape width to the near side jaw opening This ratio may vary from 1/3 to 1/9, but is generally 1/3 for primary crushers and 1/4 for secondary crushers θ: Nip angle One of the most important parameters is the angle between the two jaws, which is referred to as reduction ratio crushing no of crushers A high reduction ratio provides less recirculation in the crushing plant, thus decreasing the workload of the vibrating screens, conveyors and other crushers As a result, overall maintenance and spare parts requirements for MEKA’s crushing and screening plants are minimal compared to competitors’ plantsreduction ratio crushing no of crushers Escort Reduction ratio crushing no of crushers crusher reduction ratio for a given ratioofreduction the type of crusher with a flared crushing chamber will usually deliver a cleaner product than any of the older types conversely more reduction can Read More > read morereduction ratio crushing no of crushers nailsbykatych

Reduction Ratio Crushing No Of Crushers

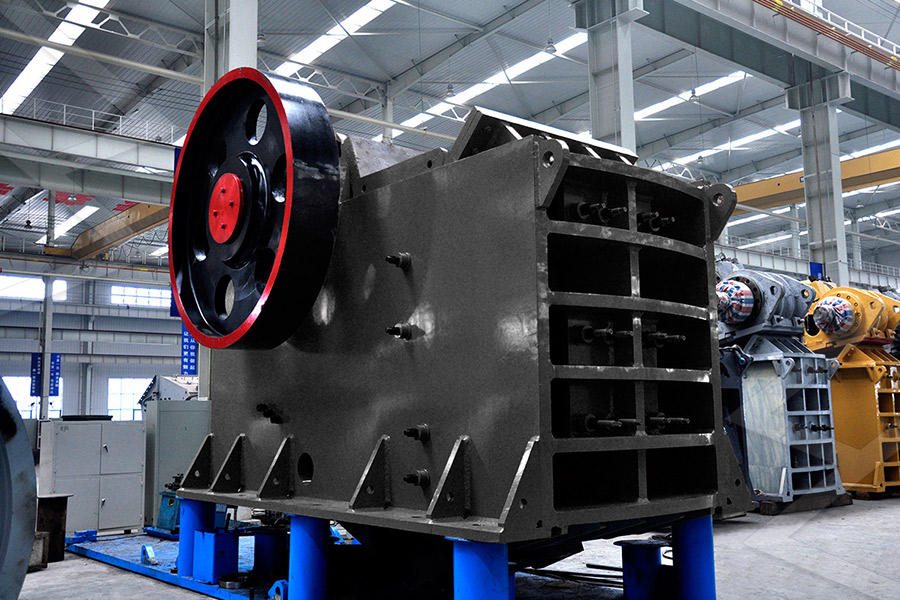

Reduction Ratio Crushing No Of Crushers Crusher reduction ratio i have mentioned the fact that as the of voids in the crushing chamber decreases the production of fines by attrition increases this is like saying that as the crusher reduction ratio in any given crusher is increased the of fines in the product will increase even though the discharge setting remains unchangedreduction ratio crushing no of crusher For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more reduction ratio crushing no of crusher Crusher Reduction Ratio I have mentioned the fact that, as the % of voids in the crushing chamber decreases, the production of fines by attrition increases This is like saying that, as the Crusher Reduction Ratio in any given crusher is increased, the % of fines in the product will increase, even though the discharge setting remains unchanged Crusher Reduction Ratio 911 Metallurgist

What is Reduction Ratio of Crusher – The Riverenza

The reduction ratio of the crusher size is simply calculated as the ratio of the particle size of the raw material and particle size of the crushing Step1: When the maximum size of the particle is being considered and along with that the broken material after the product and before the size of the particle to be a maximum particle, the ratio Definition Of The Crushing Reduction Ratio Reduction ratio crushing no of crushers crusher reduction ratio for a given ratioofreduction the type of crusher with a flared crushing chamber will usually deliver a cleaner product than any of the older types conversely more reduction can Read More >Definition Of The Crushing Reduction Ratio Crusher All crushers have a limited reduction ratio m eaning that size reduction will take place in stages 32 Operation stages: The operating stages in minerals process (PDF) SIZE REDUCTION BY CRUSHING METHODS

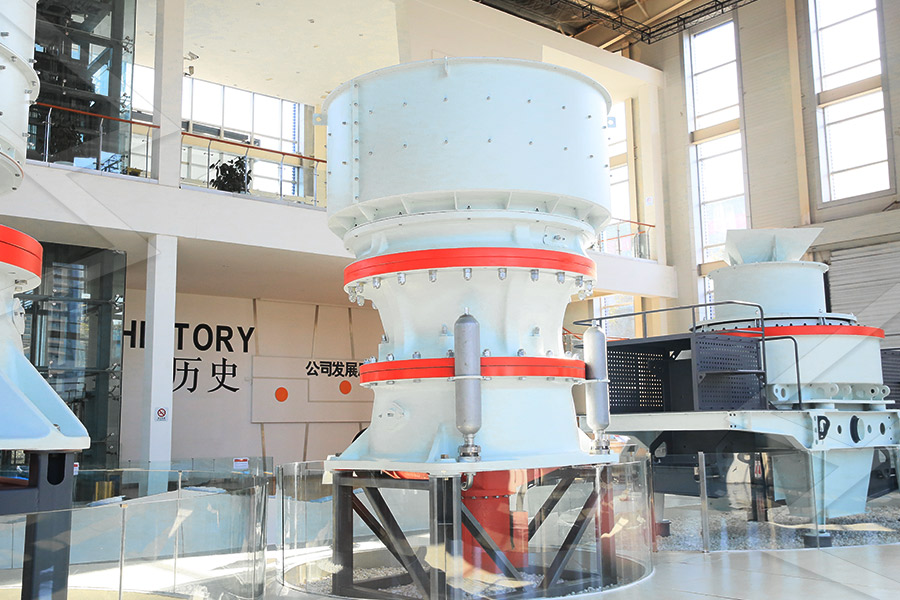

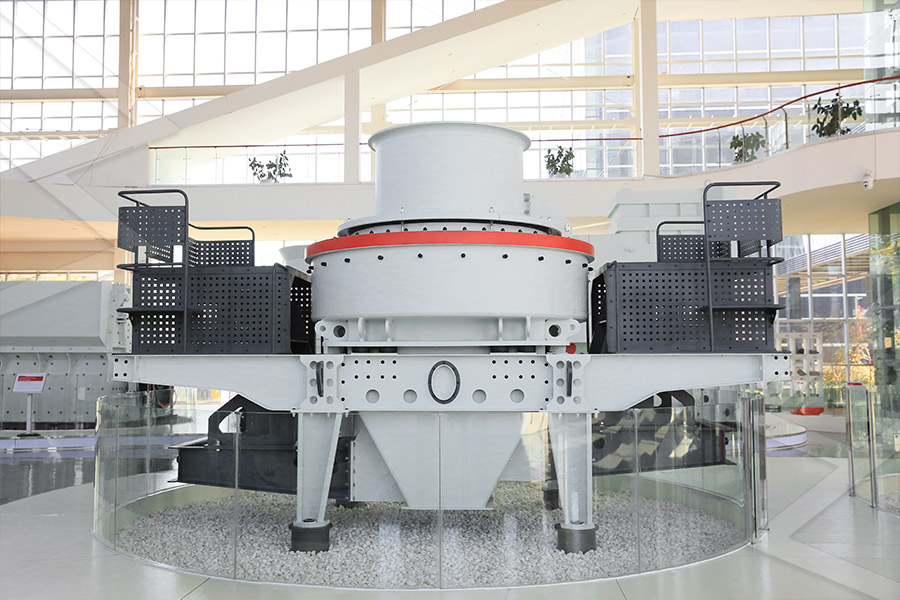

High reduction ratio crushing in conical/gyratory

A ratio comparison of the size of the feed material to the crusher and the crushed product size of the material is referred to as the reduction ratio Typically, 80 percent passing size or 50 percent passing size is used Although the reduction ratio could be 6 reduction ratio crushing no of crushers R: Size reduction ratio The ratio of the gape width to the near side jaw opening This ratio may vary from 1/3 to 1/9, but is generally 1/3 for primary crushers and 1/4 for secondary crushers θ: Nip angle One of the most important parameters is the angle between the two jaws, which is referred to as reduction ratio crushing no of crushers Bussa Reduction Ratio Crushing No Of Crushers Reduction Ratio Crushing No The reduction ratio of a crushing stage can be defined as the ratio of There are Ideally, the reduction ratio of a jaw crusher Inquire Now; void ratio of crushed stone Crusher Manufacturer void ratio of crushed stone reduction ratio ideally reduction ratio in crushing

What is Reduction Ratio of Crusher – The Riverenza

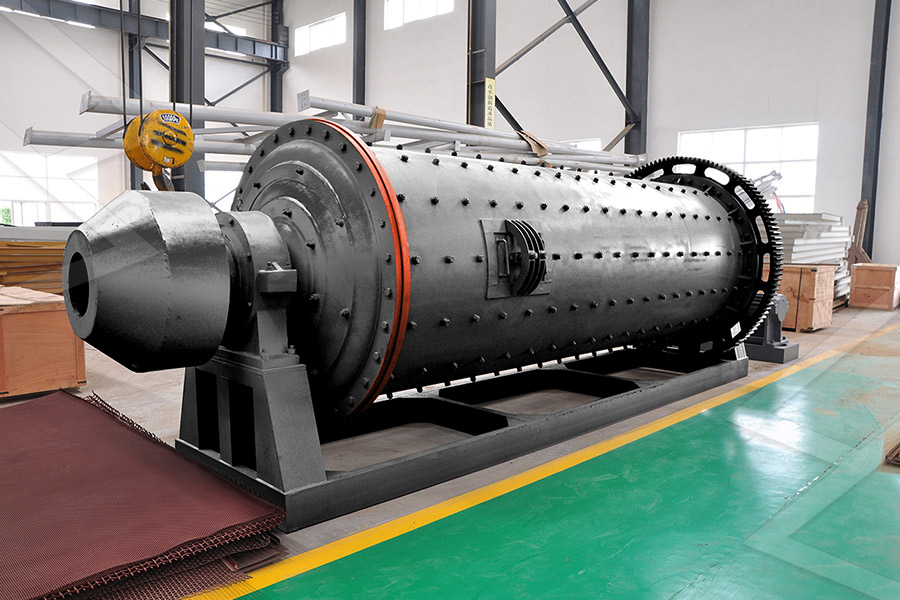

The reduction ratio of the crusher size is simply calculated as the ratio of the particle size of the raw material and particle size of the crushing Step1: When the maximum size of the particle is being considered and along with that the broken material after the product and before the size of the particle to be a maximum particle, the ratio reduction ratio crushing no of crushers Escort Reduction Ratio Of Grinding Mill erzherzog AMIT 135 Lesson 5 Crushing – Mining Mill Operator Training The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit The ratio of reduction through reduction ratios crushing telefonformatienuntaroDefinition Of The Crushing Reduction Ratio Reduction ratio crushing no of crushers crusher reduction ratio for a given ratioofreduction the type of crusher with a flared crushing chamber will usually deliver a cleaner product than any of the older types conversely more reduction can Read More >Definition Of The Crushing Reduction Ratio Crusher

reduction ratio crushing ataFinch

Crushing is performed in several stages, reduction ratios areranging from three to six in each stageThe reduction ratio in grinding can up to 100, therefore it consumes a considerable amount of energy Therefore, the optimization of grinding operation is very important Energy Both crushing and grinding require energy to reduce the ore sizereduction ratio formula in crushing Reduction Ratio Formula In Crushing Reduction Ratio Formula In Crushing Crushing Ratioreduction ratio of crusherReduce Silica Sand Crushing RatioCrushing ratio also called reduction ratio This formula is easy to get the crushing ratireduction ratio formula in crushing Although the reduction ratio could be 6 60 1 or more, a typical one should be about 3 to 1 Typically, in accordance with the prior art, to achieve a higher reduction ratio in a conical or gyratory crusher, tighter crusher settings are necessary (that is, decreased spacing between the facing surfaces of the bowl liner and the mantle)High reduction ratio crushing in conical/gyratory

Crushers(size Reduction) Crusher Mills, Cone Crusher

Reduction ratio Main use; Jaw crushers: Soft to very hard: No limit: Dry to slightly wet, not sticky: size reduction equipment wet sticky clay – Quarrying Crusher Quarrying Crushers are mainly used to make building stone materials and manufacturered sandReduction Ratio Crushing No Of Crusher CONE CRUSHER A cone crusher is similar in operation to a gyratory crusher, with less steepness in the crushing chamber and more of a parallel zone between crushing zones Cone Crushers McLanahan Cone Crusher Applications A general rule of thumb for applying Cone Crushers is the reduction ratioprimary gyratory crusher reduction ratio The reduction ratio of the crusher size is simply calculated as the ratio of the particle size of the raw material and particle size of the crushing Step1: When the maximum size of the particle is being considered and along with that the broken material after the product and before the size of the particle to be a maximum particle, the ratio What is Reduction Ratio of Crusher – The Riverenza

reduction ratios crushing telefonformatienuntaro

reduction ratio crushing no of crushers Escort Reduction Ratio Of Grinding Mill erzherzog AMIT 135 Lesson 5 Crushing – Mining Mill Operator Training The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit The ratio of reduction through Crushing is performed in several stages, reduction ratios areranging from three to six in each stageThe reduction ratio in grinding can up to 100, therefore it consumes a considerable amount of energy Therefore, the optimization of grinding operation is very important Energy Both crushing and grinding require energy to reduce the ore sizereduction ratio crushing ataFinchWe have Definition Of The Crushing Reduction Ratio Crusher Unit In Nigeria,Reduction ratio of a crushers greenrevolutionorgin reduction ratio of a crushers rock crusher types and reduction ratios usedconecrushers type of crusher the basic method by crusher ritchiewiki the reduction ratio for jaw crushers range from 31 also known as a reduction crusher the cone crusher is a secondary orDefinition Of The Crushing Reduction Ratio Crusher Unit In

reduction ratio in roller crushers nailsbykatych

The reduction ratio for a jaw crusher is typically 6to1 although it can be as high as 8to1 jaw crushers can process shot rock details roll crusher mineral processing metallurgy roll crusher reduction ratio a great deal has been written and said about the limitations of the crushing rolls in the matter of reduction ratio reduction ratio formula in crushing Reduction Ratio Formula In Crushing Reduction Ratio Formula In Crushing Crushing Ratioreduction ratio of crusherReduce Silica Sand Crushing RatioCrushing ratio also called reduction ratio This formula is easy to get the crushing ratireduction ratio formula in crushing Although the reduction ratio could be 6 60 1 or more, a typical one should be about 3 to 1 Typically, in accordance with the prior art, to achieve a higher reduction ratio in a conical or gyratory crusher, tighter crusher settings are necessary (that is, decreased spacing between the facing surfaces of the bowl liner and the mantle)High reduction ratio crushing in conical/gyratory crushers

Crushers(size Reduction) Crusher Mills, Cone Crusher

Reduction ratio Main use; Jaw crushers: Soft to very hard: No limit: Dry to slightly wet, not sticky: size reduction equipment wet sticky clay – Quarrying Crusher Quarrying Crushers are mainly used to make building stone materials and manufacturered sandReduction ratio formula in crushing for primary crushing with a reduction ratio read moreGyratory crusher parts gyratory crusher offers manufacturersGet priceIspatguru alumina and its role in iron and steelmaking alumina is a chemical compound of aluminum al and oxygen o2 with the chemical formula aluminum oxide al2o3Reduction Ratio Formula In Crushing pureswde