effect of crushing gap on the performance of a local crusher

effect of crushing gap for the performance of loc

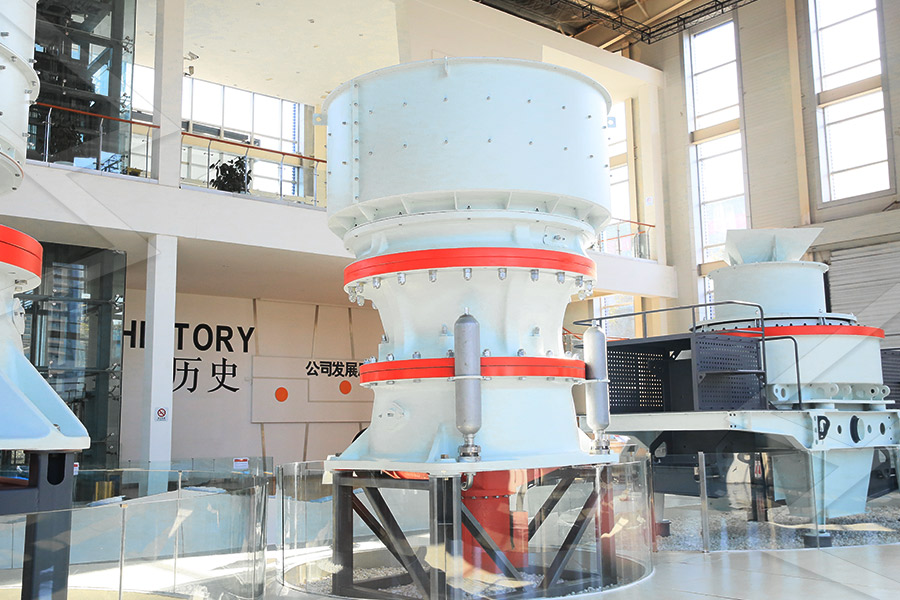

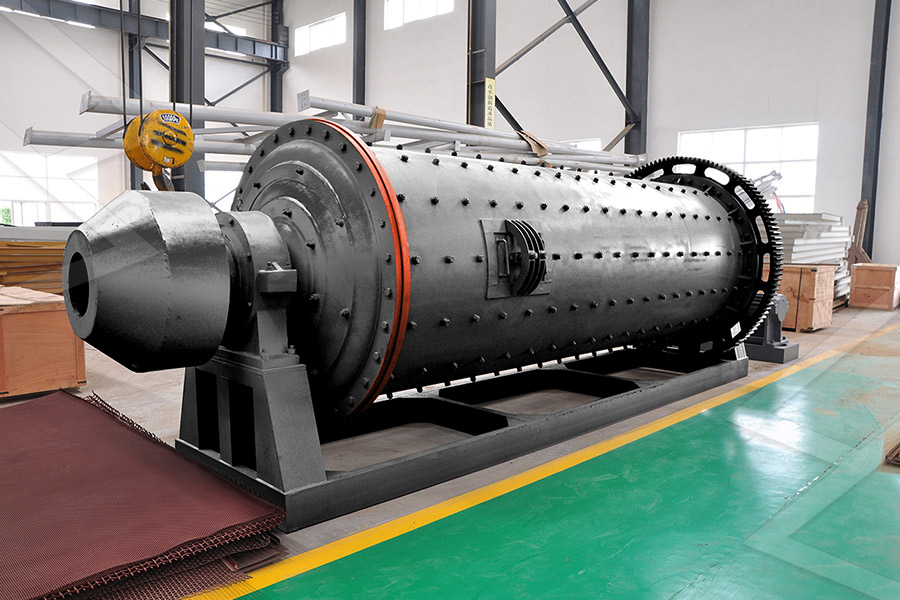

PDF Design and Evaluation of Crushing Hammer mill 23 Mar 2019 PDF A grain size reduction hammer mill for crushing corn Zea mays L The effect of hammer speed, feeding rate and screen holes diameters on grind corn geometric mean diameter within the capacity of the local farmers, using standard component and local productionconsumption gap in Egypt The effect of the undersize in the feed upon the capacity of the crusher depends upon several factors If the crusher is a primary breaker, and the discharge opening is large, undersize will usually sift readily through the voids between the large Effect of Feed Rock Size Distribution on Crusher A cone crusher in a secondary crushing application will typically work with a 35:1 to 5:1 reduction ratio Tertiary cone crusher configurations typically work with a reduction ratio of 25:1 to 4:1 The reduction ratio is defined as the ratio of the feed size for which 80 per cent will pass (F80), divided by the product size for which 80 per The pros and cons of cone crusher applications – Quarry

Crusher an overview ScienceDirect Topics

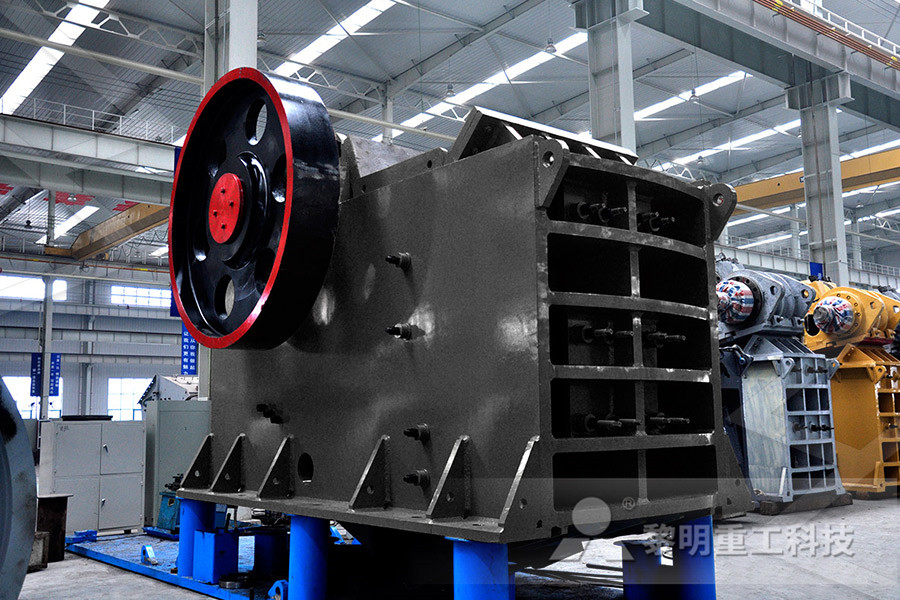

The maximum crushing action is created by closing the gap between the hard crushing surface attached to the spindle and the concave fixed liners mounted on the main frame of the crusher The gap opens and closes by an eccentric drive on the bottom of the spindle that causes the central vertical spindle to gyrate Jaw crusher performance can be optimised for increased aggregate quality To close this knowledge gap, a jaw crusher parameter test is designed based on previous research into crushing and aggregate production, presented in the following: Another possibility is to include other jaw crushers to assess the effect of crusher geometry 5Influence of jaw crusher parameters on the quality of Effects Of Moisture On Crusher Performance Moisture effect in coal crusher crusher search effect of moisture in cement grinding mill to find your 13 properties of coal it is a soft coal composed mainly of volatile matter and moisture content a 1 oxidation of coal has the same effect as 1 ash in coal wind losses may More Details Get PriceMoisture Effect In Coal Crusher labellepoulefr

(PDF) Modelling of the HPGR crusher ResearchGate

This is similar to the breakage action in the precrushing zone, where large particles breaks sequentially in order to be smaller than the critical gap to enter the grinding zone (Morrell et al The opening of the primary crusher, for example, will affect the throughput of secondary crushing, and secondary crushing will, in turn, influence tertiary production and so on How to check the opening of the jaw crusher Whenever a jaw crusher is off and at rest (stopped), it will remain in the open position at its openside setting (OSS)Measuring the crusher setting 911 Metallurgist crushing circuit since the crushers are running on a constant ES and the CSS is set and reset manually The outcome of the study presents an insight into the optimization of the Mowana mine crushing circuit through the design of a selftuning controller for the cone crusher and for prototyping, parameters of a PID controllerMODELLING, SIMULATION AND OPTIMISATION OF A

Mobile Crushers Mobile Crushing Plant

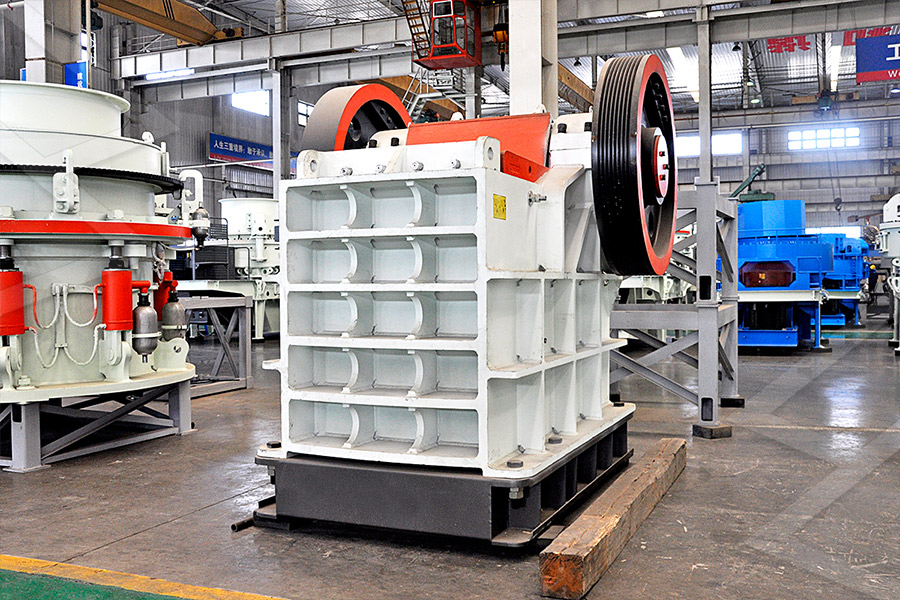

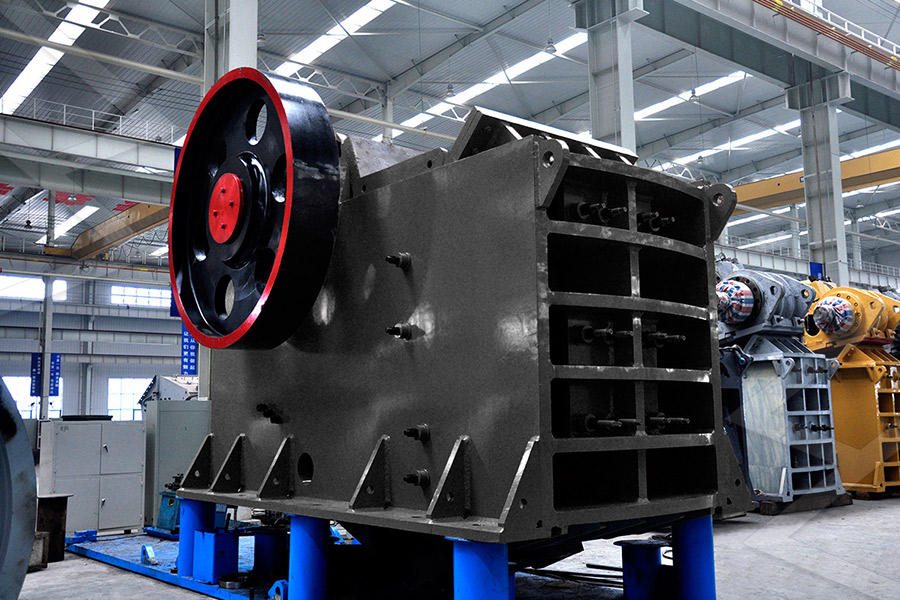

Mobile Crushers Innovation Advantages Our mobile crusher can be used in one stage of crushing for separate operation or complete joint operations with other crushing and screening portable plants to achieve twostage, threestage or fourstage crushing, so that various crusher screening requirements could be satisfied Prediction of crusher performance has been focused on, since crushing is a vital process for both industries In this thesis a method for prediction of cone crusher performance is presented(PDF) Cone Crusher Performance ResearchGate Effect of machine controls on crusher performance61 Effect of change in CSS The CSS is the most important machine control parameter for the cone crusher It can vary due to wear or intentionally as a result of operator or machine control decisions Here we explore the effect of small changes in the CSS on the flow and crusher performanceAnalysis of cone crusher performance with changes in

EFFECT OF MACHINE DESIGN ON PERFORMANCE OF

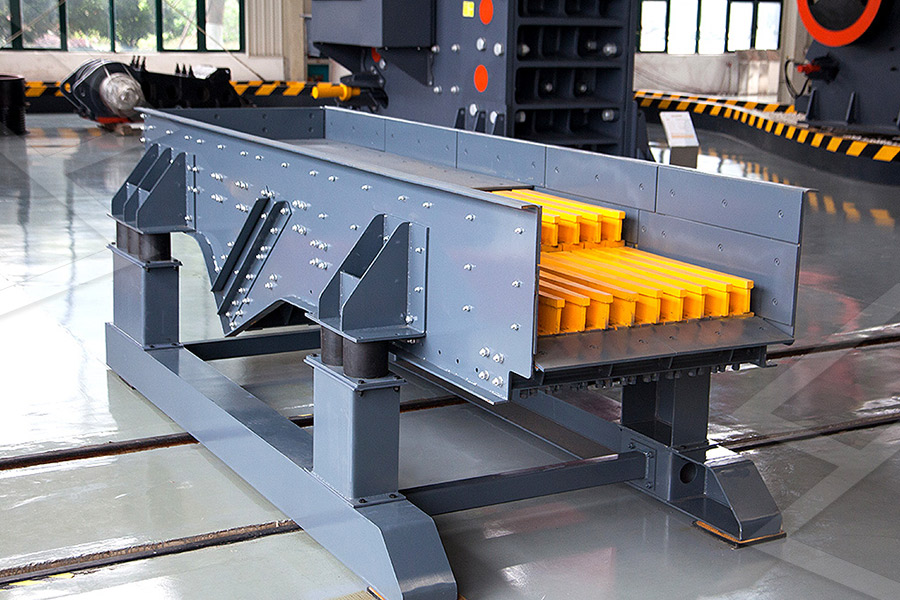

EFFECT OF MACHINE DESIGN ON PERFORMANCE OF ORIGINAL EUCALYPTUS BARK CRUSHING MACHINE The crusher blades, comprise 144 pieces, and require replacing, typically after 2 months, primarily related to The gap between each crushing blade in each section is 60 mm The minimum gap between blades in section 12, 23, 45 and 56 is 90mm Effect Of Stone Crushing On The Lungs Research In Effect Of Crushing Gap On The Performance Of A Local Crusher Effect of stone crushing on the lungs research in palestine our effect of stone crushing on the lungs research in palestine mobile impact crusher putting crushing and screening process on wheels really boosts process efficiency Pie down graded crushing stone Manufacturer Of Figure 5: Variation in Crusher Feed % Coarse The effect of crusher feed size on product sizing is shown in Figure 6 page I196 For a constant setting or gap, the product % coarse is directly related to the feed % coarse In other words, the shape of the feed size distribution is reflected in the product distribution OtherThe Importance of Primary Crushing in Mill Feed Size

(PDF) Modelling of the HPGR crusher ResearchGate

This is similar to the breakage action in the precrushing zone, where large particles breaks sequentially in order to be smaller than the critical gap to enter the grinding zone (Morrell et al Production capacity, product shape good Impact crusher is a lowspeed, multicrushing chamber impact of the crushing equipment, the line speed reduced by 20% 25%, broken relatively large, can make three broken into two or a broken, access to a higher production And the vertical impact crusher has the functions of crushing and shapingVertical Impact Crusher DesignFour roller crusher, also named four teeth roller crusher, which has successfully replaced the hammer crusher used by most power plants, it used for crushing coal, lump coal and wet coal Four roller crusher has features: stable and high yield, uniform particle size, and environmental protection Xinxiang four roller crusher manufacturer: 86373【Four Roller Crusher】/four teeth roller crusher/four

Impact Crusher Sanme

The impact crusher is also called impact crusher It is mainly used in metallurgy, chemical industry, building materials, hydropower and other materials that often need to be relocated, especially for the operation of fluid stones in highways, railways, hydropower projects, etc Different types, scales and requirements of finished materials adopt multiple configurations Portable Crusher Work Independently In actual situations, there may be a large amount of mineral soil which doesn’t need crushing If users don’t separate it from materials and just feed them into the coarse crushers, the burden on coarse crushers may Portable Crushing Plants Portable Rock Crusher Prediction of crusher performance has been focused on, since crushing is a vital process for both industries In this thesis a method for prediction of cone crusher performance is presented(PDF) Cone Crusher Performance ResearchGate

EFFECT OF MACHINE DESIGN ON PERFORMANCE OF

EFFECT OF MACHINE DESIGN ON PERFORMANCE OF ORIGINAL EUCALYPTUS BARK CRUSHING MACHINE The crusher blades, comprise 144 pieces, and require replacing, typically after 2 months, primarily related to The gap between each crushing blade in each section is 60 mm The minimum gap between blades in section 12, 23, 45 and 56 is 90mm This is similar to the breakage action in the precrushing zone, where large particles breaks sequentially in order to be smaller than the critical gap to enter the grinding zone (Morrell et al (PDF) Modelling of the HPGR crusher ResearchGate Figure 5: Variation in Crusher Feed % Coarse The effect of crusher feed size on product sizing is shown in Figure 6 page I196 For a constant setting or gap, the product % coarse is directly related to the feed % coarse In other words, the shape of the feed size distribution is reflected in the product distribution OtherThe Importance of Primary Crushing in Mill Feed Size

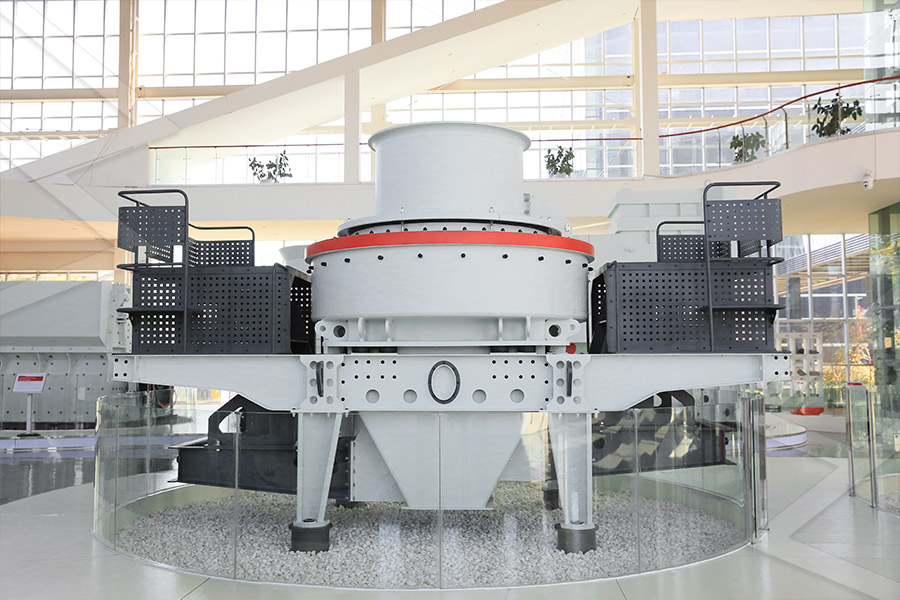

Vertical Impact Crusher Design

Production capacity, product shape good Impact crusher is a lowspeed, multicrushing chamber impact of the crushing equipment, the line speed reduced by 20% 25%, broken relatively large, can make three broken into two or a broken, access to a higher production And the vertical impact crusher has the functions of crushing and shaping The secondary crushing stage is widely used in building materials, mining, metallurgy, chemical industry, etc Both hydraulic cone crusher and impact rock crusher machine all belong to the secondary stone crusher, there are still some differences in the usage of two stone crushing plant What Are the Main Differences Between the Impact Rock Crusher and Hydraulic Cone CrusherThe Impact Rock Crusher Machine VS Hydraulic Cone Crusher Teeth roller coal crusher principle is: the fuel enter from up, and discharge directly from bottom outlet, without secondary crushing To achieve the crushing purpose through crushing and screening by snap action between teeth, the grain evenly, over powder rate is very low, and its broken particle size can be quickly adjusted by the screw, to fully meet the requirements of coalfired 【Double teeth roller crusher】/roller crusher/double roller

Impact Crusher Sanme

The impact crusher is also called impact crusher It is mainly used in metallurgy, chemical industry, building materials, hydropower and other materials that often need to be relocated, especially for the operation of fluid stones in highways, railways, hydropower projects, etc Different types, scales and requirements of finished materials adopt multiple configurations 8:1 maximum reduction ratio for compression crushing, this is normally used as a primary crusher Jaws perform well in many materials Yields low wear cost per ton in hard abrasive deposits, minimal fines but produces little finished (under 1”) product which places more load on the crushers downstream in the circuitCrushing 101 » Masaba Manufacturing Crushing process of oilseeds is vital for improvement of flakes quality and processing capacity of flaking machine, thus oilseeds crusher is the key equipment for oil seeds preprocessing workshop; crushing process for prepressed oil cakes is good for extracting edible oil out in oil solvent extraction or second pressing sectionOilseed Crushing Machine Key Equipment for Oilseeds