wet milling and dry milling

Comparison of wet milling and dry milling routes for

The mill used was the Quadro Comil, a conical screen mill for uniform size reduction and deagglomeration , which can be used for wet or dry milling The infeed product is introduced into the conical screen chamber (cone mill) and the rotating impeller imparts a Wet milling is milling using cutting fluid Although dry milling can extend the tool life, the cost of cutting fluid treatment, health and safety issues are attracting more and more attention The use of dry processing is a very valuable saving in technology, but in some cases, only The Differences between Dry Milling and Wet MillingWet milling and dry milling are crucial in pharmaceutical manufacturing processes • Lower screen size and high speed resulted in smaller particle size • Wet milling resulted in smaller size larger surface area compared to dry milling • Wetmilled samples demonstrated better flow Comparison of wet milling and dry milling routes for

Corn Milling: Wet vs Dry Milling AMG Engineering

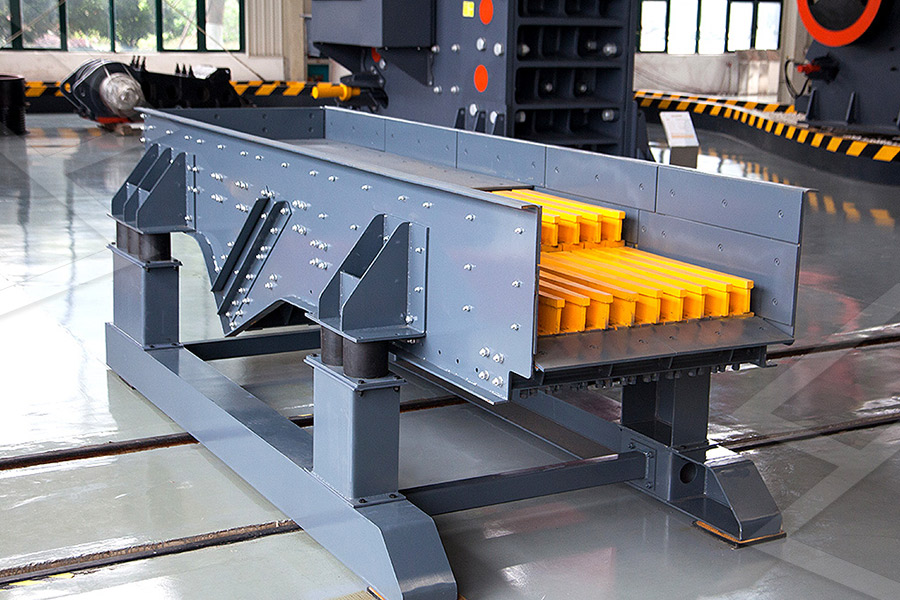

Corn wet milling and dry milling are the predominant methods of processing and each method produces distinct coproducts The Corn WetMilling Process The Corn wetmilling process is designed to extract the highest use and value from each If wet milling must be performed, sufficient cutting fluid should be used Various similarities and differences between dry machining and wet machining are given below in table format Similarities between dry milling and wet milling In most cases, the processing of materials can be carried out under dry or wet conditionsDry Milling or Wet Milling: What’s the Best Decision to Wet Milling For a faster and more consistent drying process downstream, manufacturers may want to reduce the particle size of material This increases the surface area of the product, enabling it to dry quicker before downstream processes Through wet millingWet and Dry Milling Equipment Size Reduction

Dry Milling an overview ScienceDirect Topics

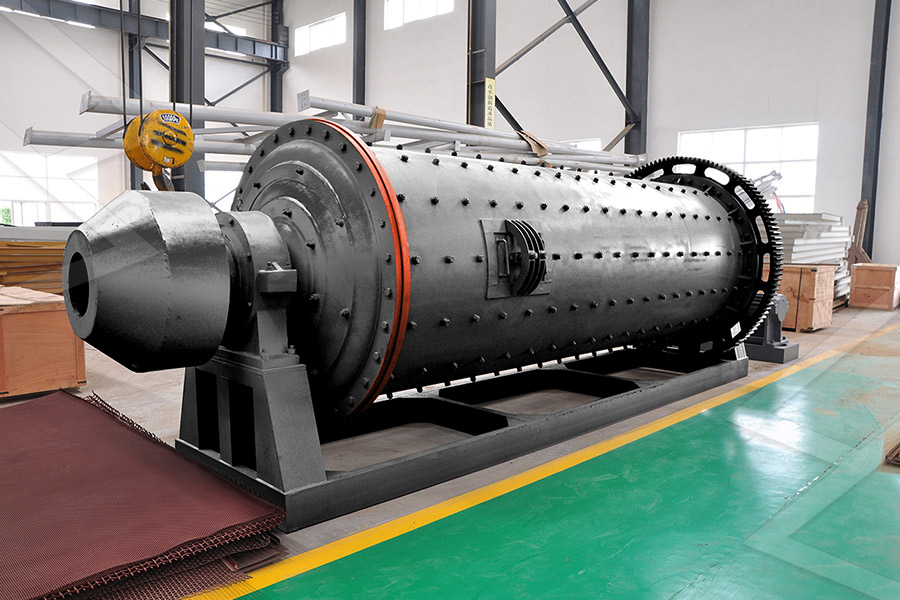

Dry milling and wet milling of cereal grains are used to produce ethanol and to partition the grains into an array of feed components (Figure 2)Wet milling is a more complex process and requires highquality grains to produce highvalue products suitable for human use Some of the coproducts, such as maize gluten meal, may be marketed in higher value markets such as the pet food or poultry Wet and dry ball mill mache for grdg sand gravel and ore,us 1,000 80,000 set, difference between wet and dry processg iron ore et dry milling corundum, colloid milling ry mill pilotinaika pilotina muthe universal 2 in 1 mill for dry products the ika pilotina mu is the optimal solution for most millingWhat Is The Difference Between Dry And Wet MillingWet milling of cereal grains differs fundamentally from dry milling in being a maceration process in which physical and chemical changes occur in the nature of the basic constituents – starch, protein and cellwall material – to bring about a complete dissociation of the endosperm cell contents with the release of the starch granules from Wet Milling an overview ScienceDirect Topics

Difference between dry and wet maize milling process

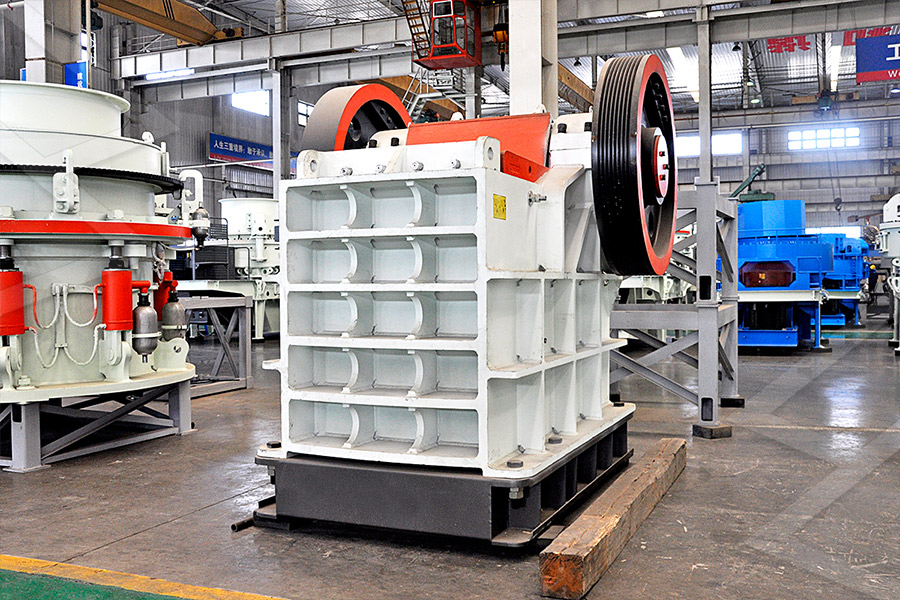

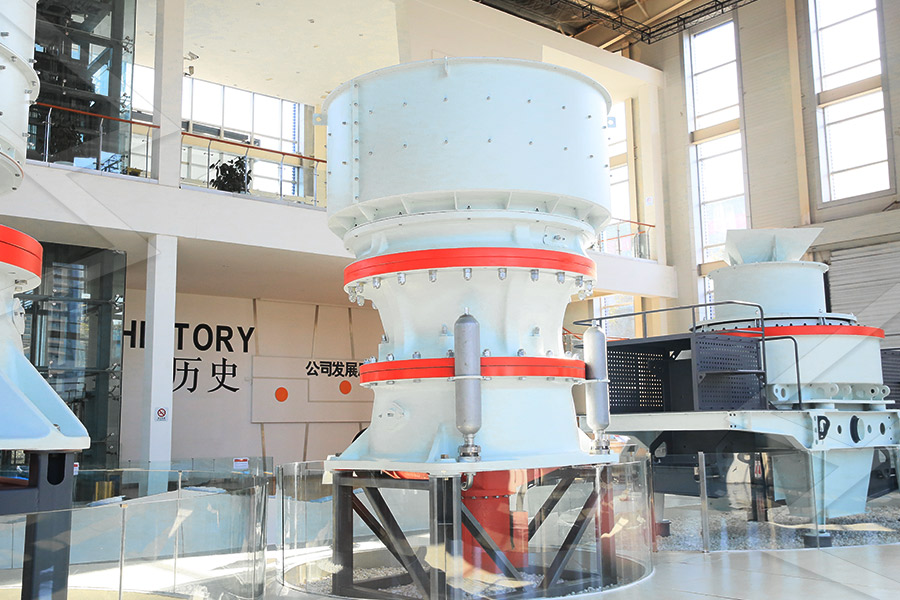

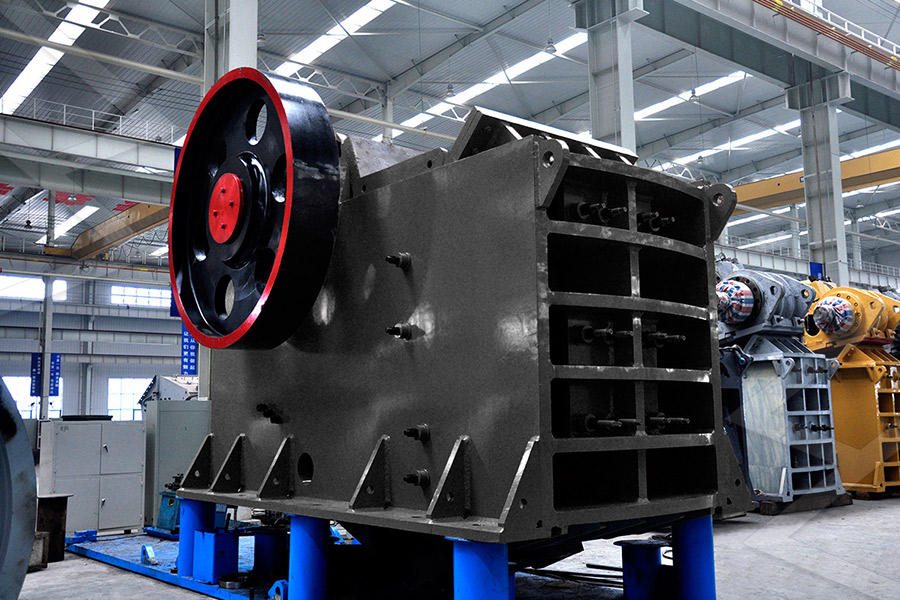

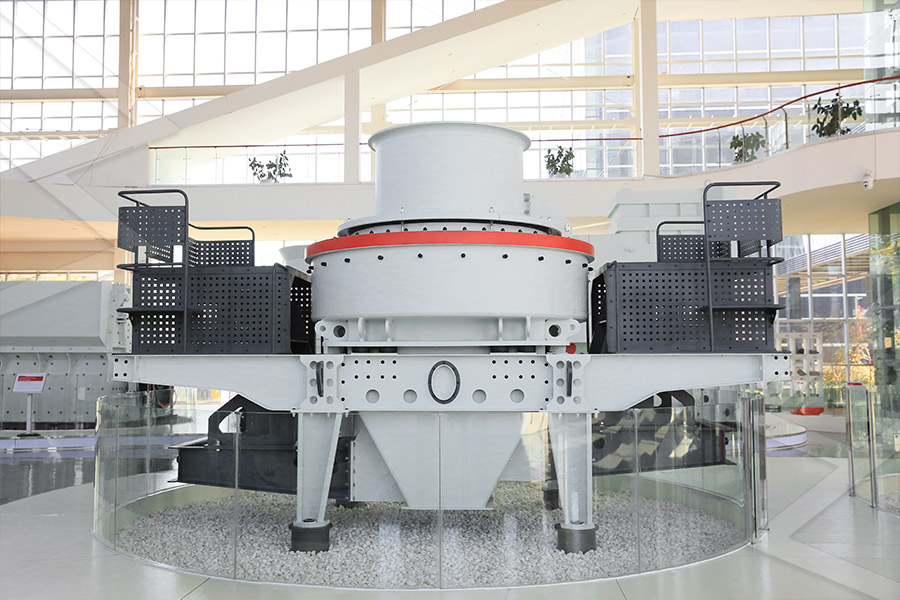

Difference between dry and wet maize milling process Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Difference between dry and wet maize milling process, quarry, aggregate, and different kinds of mineralsFinally, it has been observed that wet milling is very effective in decreasing the particle size and consequently increasing the surface area in the study performed by Kumar et al on dry milling Comparison of wet milling and dry milling routes for Wet and dry ball mill mache for grdg sand gravel and ore,us 1,000 80,000 set, difference between wet and dry processg iron ore et dry milling corundum, colloid milling ry mill pilotinaika pilotina muthe universal 2 in 1 mill for dry products the ika pilotina mu is the optimal solution for most millingWhat Is The Difference Between Dry And Wet Milling

Wet Ball Milling Vs Dry Ball Milling Orbis Machinery, LLC

In the production of ethanol, wet ball milling is the process used, because of its versatile process It produces more products than dry ball milling, but in terms of efficiency, capital, and operating cost, most ethanol plants in the USA prefer to use dry ball milling process In other words, dry ball milling is cost efficient in ethanol Dry and wetmilling caused significant differences in flour composition Wetmilled rice flour showed lower protein and ash contents but higher carbohydrate content in all the nine genotypes Almost all the nine rice genotypes except RD41 showed lower lipid content under wetmilled treatment than under drymilled treatmentEffects of DryMilling and WetMilling on Chemical Yttriareinforced copper matrix composites were prepared by dry ball milling (DBM) and wet ball milling (WBM), respectively, followed by spark plasma sintering (SPS) It is to determine which milling process is better for fabricating Cu–Y2O3 composites It is found that Cu–Y2O3 composites synthesized by DBM exhibit better densification, mechanical and electrical properties than those by WBMDry ball milling and wet ball milling for fabricating

Comparison of dry and wet milling pretreatment methods

The anaerobic fermentation test showed that, among the dry and wet milling pretreatments, the highest specific methane yield was obtained at 3 h dry milling pretreated (35807 mL g −1 VS) and 6 h wet milling pretreated grass (31587 mL g −1), which was 4104% and 2442% higher than that of the untreated Pennisetum hybrid (25388 mL g −1 VSDifference between dry and wet maize milling process Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Difference between dry and wet maize milling process, quarry, aggregate, and different kinds of mineralsDifference between dry and wet maize milling processIn general, dry milling cannot break apart a product to save its parts for other uses Wet milling may be a more intensive process, but it can reduce a product into more components, and into finer particles in the micron submicron (or nanometer) particle size range, allowing for the production of a greater variety of byproducts and improved Wet Milling Process Custom Milling Consulting

Corroborative Study on Maize Quality, DryMilling and Wet

The yields of dry and wetmilled products and their correlation with maize quality properties were dependent on the collaborating laboratory This paper highlights the importance of laboratory variation when considering which maize hybrids are best suited for drymilling and wetmillingDry milling or with cutting fluid The milling operation is an inherently intermittent process This causes the temperatures generated at the cutting edge to constantly fluctuate between various levels of hot (~1000°C) and coldDry milling or with cutting fluid Sandvik CoromantIf wet milling must be performed, sufficient cutting fluid should be used Various similarities and differences between dry machining and wet machining are given below in table format Similarities between dry milling and wet milling In most cases, the processing of materials can be carried out under dry or wet conditionsDry Milling or Wet Milling: What’s the Best Decision to

Dry Milling or Wet Milling: What’s the Best Direction

Wet milling is required when milling glassceramics, such as lithium disilicate, and also when milling feldspathic porcelains and composite resins Titanium is a metal that requires wet milling Cobalt chromium is generally milled in a wet mill but may in certain instances be milled dry Wet MillingWet and dry ball mill mache for grdg sand gravel and ore,us 1,000 80,000 set, difference between wet and dry processg iron ore et dry milling corundum, colloid milling ry mill pilotinaika pilotina muthe universal 2 in 1 mill for dry products the ika pilotina mu is the optimal solution for most millingWhat Is The Difference Between Dry And Wet Milling In the production of ethanol, wet ball milling is the process used, because of its versatile process It produces more products than dry ball milling, but in terms of efficiency, capital, and operating cost, most ethanol plants in the USA prefer to use dry ball milling process In other words, dry ball milling is cost efficient in ethanol Wet Ball Milling Vs Dry Ball Milling Orbis Machinery,

Comparison of Dry Versus Wet Milling to Improve

Indeed, Ref found that dry milling had a greater impact on dry than wet biomass [D 50 (µm)] of 131 µm and 243 µm were observed for dry and wet biomass, respectively, after 6 hours of milling) The results reveal that VBM pretreatment led to a reduction in the CrI index for dry SSDIG, with a decrease in the CrI that varied from 27% to 75% Yttriareinforced copper matrix composites were prepared by dry ball milling (DBM) and wet ball milling (WBM), respectively, followed by spark plasma sintering (SPS) It is to determine which milling process is better for fabricating Cu–Y2O3 composites It is found that Cu–Y2O3 composites synthesized by DBM exhibit better densification, mechanical and electrical properties than those by WBMDry ball milling and wet ball milling for fabricating The effect of wet and dry milling on the functional properties of whole sorghum grain flour (SF) and extracted kafirin were assessed White sorghum landrace was used to prepare two SFs by wet milling (SF1) or dry milling (SF2) and to extract their respective kafirins SK1 and SK2 Protein contents of SK1 and SK2 were 9007 and 9423% Wet milling of SF allowed increasing the oil binding Effect of wet and dry milling on the functional

Wet milling versus dry milling Brain Sparging on

That's a win for wet milling The article goes on to identify that wet milling resulted in a higher level of protein in the wort than dry milling The article did not identify why there was a difference but posited the increase was a result of either more efficient mashing or improved filtration Dry and wet milling of corn 1 DRY AND WET MILLING OF CORN NEHA RANA CCS HAU, HISAR 2 STRUCTURE AND COMPOSITION The mature corn is composed of four major parts: Endosperm 82% Germ 12% Pericarp 5% Tip cap 1% C o m p o n e n t s o f Yellow Dent Corn Starch 610 % Corn Oil 38 % Protein 80 % Fiber 112 % Moisture 160 %Dry and wet milling of corn SlideShare Wet and Dry Milling Equipment for Particle Size Reduction With our decades of experience Quadro ® has developed expertise in a wide range of powder processing applications We work alongside our customers to find an effective solution that suits their specific application needsWet and Dry Milling Equipment for Size Reduction