ne crushers requires

A Detailed Overview of Cone Crushers and What You

Most cone crushers have a feed opening size of 514", so material that's larger than the maximum size allowable will need a first stage of crushing before they can be fed into a cone crusher Final Product Isn't Uniform Cone crushers do an excellent job of providing finished material that's relatively homogenousSep 04, 2014 You require to make use of cone crushers that can increase your profitability Cone Crushers Perth That Can Increase requires cone crushers get price Cone Crushers Cone Crushers Requires ekliefkrismiscozaThe system requires a tensioning arrangement for the motor to run optimally Typically belt drive cone crushers are more expensive and time consuming to maintain than their direct drive Belts can also slip and reduce crushing efficiency Belt drives give operators increased flexibility in where the motor is Aggregate Equipment Review – Cone Crushers: Direct

Cone Crushers McLanahan

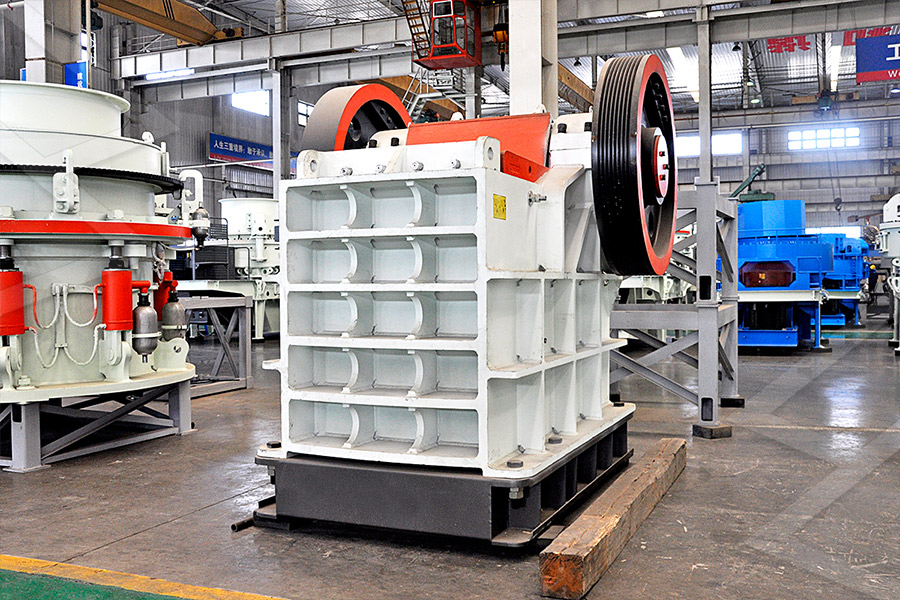

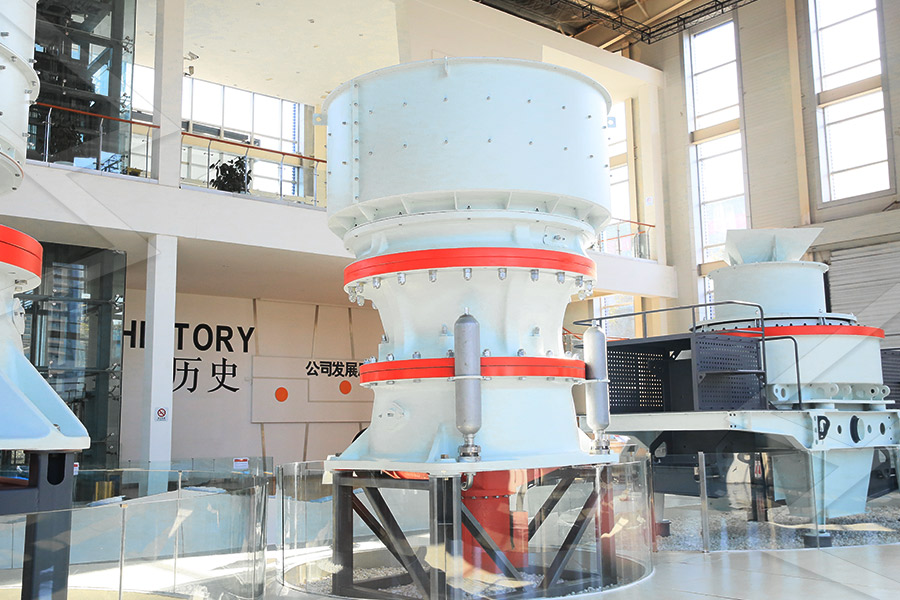

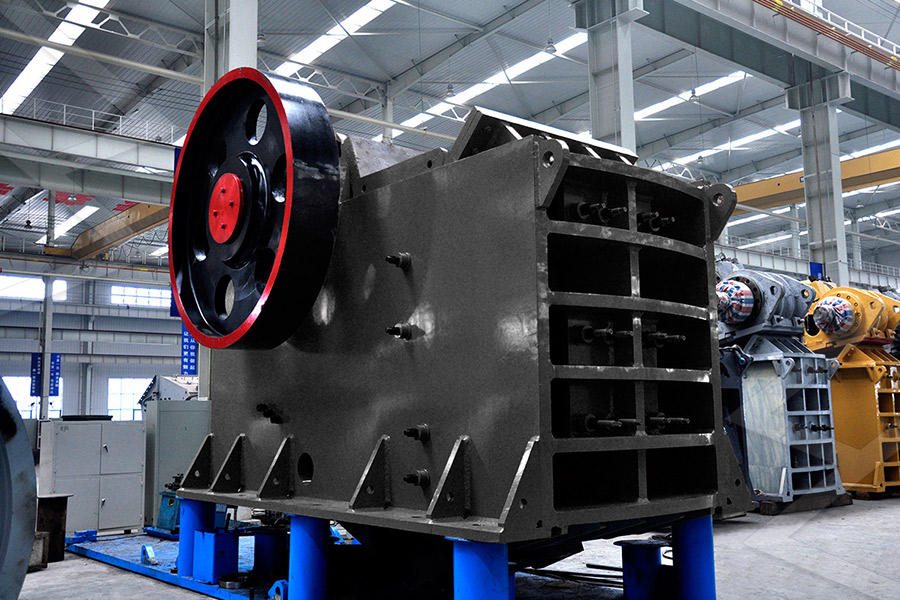

Cone Crushers A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel Final sizing and reduction is determined by the closed side 3 57SBS and 52SBS cone crushers in the field proven performance, proven reliability For more than a century, aggregate and mining professionals who require the highest productivity, best reliability and lowest cost per ton have turned to Telsmith cone crushers for consistent performance The experience shows in today’s comprehensive linecone crushers TelsmithCONETECH cone crushers are equipped with Hydraulic AntiSpin System The system prevents the head from spinning when running with intermittent feed The cone crusher requires no additional resetting or maintenance and is designed to work out of the boxReliable Cone Crushers CONETECH ENGINEERING

NORDBERG® GP SERIES CONE CRUSHER Pilot

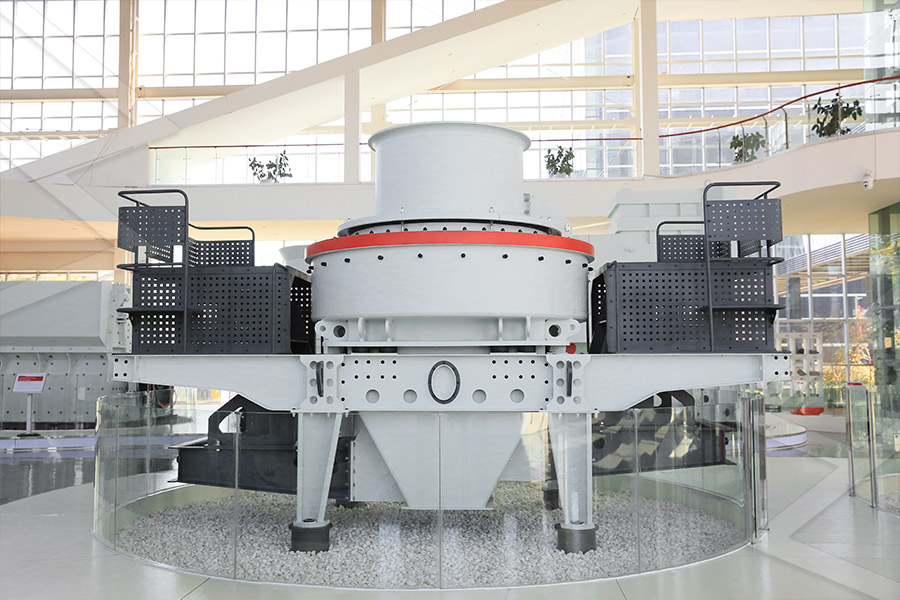

GP Series crushers are optimized for your crushing needs, whether your aggregate or mining process requires high reduction, firstclass cubicity or great capacity BENEFITS High and stable performance; Versatility; Costeffective installation; Easy and safe to use and maintain; Environmentally friendly Cone crushers are an integral part of any comminution process – but how do you know if your process requires a live shaft model or a fixed shaft unit? Mark Utecht explains the differences Trio cone crushers, available through the Weir Group, offer robust reduction for medium or above hardness feed material and are suitable for secondary, tertiary or (if the application requires) quaternary Moving vs fixed cones: understanding the differences The machine requires only one accumulator to operate safely and reliably Should an accumulator fail, an internal relief valve within the dual acting tramp release cylinders provides an immediate alternative protection of the Raptor cone crusher from severe and costly structural damage An additional safety feature standard on all Raptor cones isRaptor XL900 Cone Crushers focusonaggregates

The Benefits Of An Impact Crusher Portable Plant

Since jaw crushers and cone crushers are often used together, capital costs are high An impact crusher can be used as both a primary and secondary crusher Portable plant operations that use cone and jaw crushers require up to three different trailers Each crusher requires Cone Crushers Perth That Can Increase requires cone crushers get price Cone Crushers Crushing and Screening The range of mobile cone crushers are suitable for secondary and tertiary crushing in direct feed applicationsCone Crushers Requires ekliefkrismiscozaCONETECH cone crushers are equipped with Hydraulic AntiSpin System The system prevents the head from spinning when running with intermittent feed The cone crusher requires no additional resetting or maintenance and is designed to work out of the boxReliable Cone Crushers CONETECH ENGINEERING

Cone Crushers McLanahan

Cone Crushers A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest pointCone crushers are critical pieces for aggregate production, mineral processing operations, and recycling applications They’re typically a secondary or tertiary rock crusher and produce a fine or mediumsized aggregate material Since cone crushers have a large feed opening and small discharge sizes, this type of aggregate equipment has a high crushing ratio, making them quite efficient on Aggregate Equipment Review – Cone Crushers: Direct Drive Accumulators are a maintenance item that requires significant attention While many crushers have one accumulator per cylinder, we have analysed the core requirements of the 50 series and determined that only one accumulator is needed New to the RX50 series and to the cone crusher market is the integration of 3D laser scanning into the Raptor® Cone Crusher a gamechanger for both production

NORDBERG® GP SERIES CONE CRUSHER Pilot Crushtec

The optimized design of the ® GP Series™ castings enables the use of a higher power rating than any other cone crusher with an equal head diameter The castings design together with highquality components make it possible to maintain high crushing performance in the toughest conditions High crushing forces, excellent cavity geometry and proven kinematics result in first crushers are mostly cone crushers In situations where very high cubicity is required, the final crusher may alternatively be an impact crusher if the rock is particularly difficult to shape(PDF) Cone Crusher Performance ResearchGate • The large hydraulic piston requires only low working pressure • Only one pump is needed, and a single hydraulic line and a control valve Crusher protection system Pressure monitor (nonautomated crushers) In Gyracones that are not supplied with the optional Crusher Management System (CMS), a pressure monitor system is suppliedGyracone J Series Cone Crushers TransDiesel

Raptor XL900 Cone Crushers focusonaggregates

to replace cone crushers with a 59inch (15 m) head diameter or larger without major modifications to the foundation or feed arrangement Security Raptor cone crushers employ “Fail Safe” hydraulics to ensure the machines stay protected from mechanical overload should an accumulator bladder fail The machine requires only oneSince jaw crushers and cone crushers are often used together, capital costs are high An impact crusher can be used as both a primary and secondary crusher Portable plant operations that use cone and jaw crushers require up to three different trailers Each crusher requires its own chassis, then an additional one is required for a portable screenThe Benefits Of An Impact Crusher Portable Plant Titan™ cone crushers are engineered to deliver uncompromising productivity, safety and easeofmaintenance for maximum uptime in tough, abrasive applicationsAstec Titan® Cone Crushers Astec

Raptor® Cone Crushers Smart cone crushers with

Raptor cone crushers have flexibility of speed, giving them unequalled versatility and productivity Every crushing project is different and requires a unique solution That’s why the range of Raptor cone crushers is configurable to meet your unique needs You can operate them, secure in the knowledge that your most common challenges are beingMSP Cone Crushers use the Symons Principle of crushing – each cycle is timed so the feed material and the upward thrust of the crushing head meet at the moment of maximum impact Combining the optimum speed of gyration and the large eccentric throw produces two important results Easy to operate control panel that only requires one MSP Cone Crushers McLanahan Request a Quote • The large hydraulic piston requires only low working pressure • Only one pump is needed, and a single hydraulic line and a control valve Crusher protection system Pressure monitor (nonautomated crushers) In Gyracones that are not supplied with the optional Crusher Management System (CMS), a pressure monitor system is suppliedGyracone J Series Cone Crushers TransDiesel

How to maximize cone crusher performance Heavy

Gyratory crushers are generally used for primary crushing, whereas cone crushers are used for secondary or tertiary crushing Singlecylinder hydraulic cone crusher Benefits of this type of cone crusher include low operating costs, less consumption of wear parts, and produce a uniform particle sizeThe machine is also equipped with Hydraulic AntiSpin System requires no resetting or maintenance which is preventing the head from spinning when running with intermittent feed By the help of this mechanism, wearing of mantle and bowl liner will be less and production will be much more cubical and homogeneous All the cone crushers are Cone Products > Cone gursantrSince jaw crushers and cone crushers are often used together, capital costs are high An impact crusher can be used as both a primary and secondary crusher Portable plant operations that use cone and jaw crushers require up to three different trailers Each crusher requires its own chassis, then an additional one is required for a portable screenThe Benefits Of An Impact Crusher Portable Plant

Cedarapids CRC450X Portable Cone Crusher Plant

Home / Our Equipment / Crushing / Cone Crushers / Cedarapids CRC450X Portable Cone Crusher Plant New equipment for sale Cedarapids CRC450X Portable Cone Crusher Plant 400 hp cone crusher built for portability and applications involving hard abrasive materials *Requires The same approach for rock particle modelling was further on applied to a H6000 cone crusher (Quist, 2012) Other attempts on modelling the cone crusher have recently by presented by Li et al, 2014, Delaney et al, 2015 and Cleary and Sinnott (2015) There are mainly three different approaches for modelling the rock material breakage in DEMCone crusher modelling and simulation using DEM to replace cone crushers with a 59inch (15 m) head diameter or larger without major modifications to the foundation or feed arrangement Security Raptor cone crushers employ “Fail Safe” hydraulics to ensure the machines stay protected from mechanical overload should an accumulator bladder fail The machine requires only oneRaptor XL900 Cone Crushers focusonaggregates